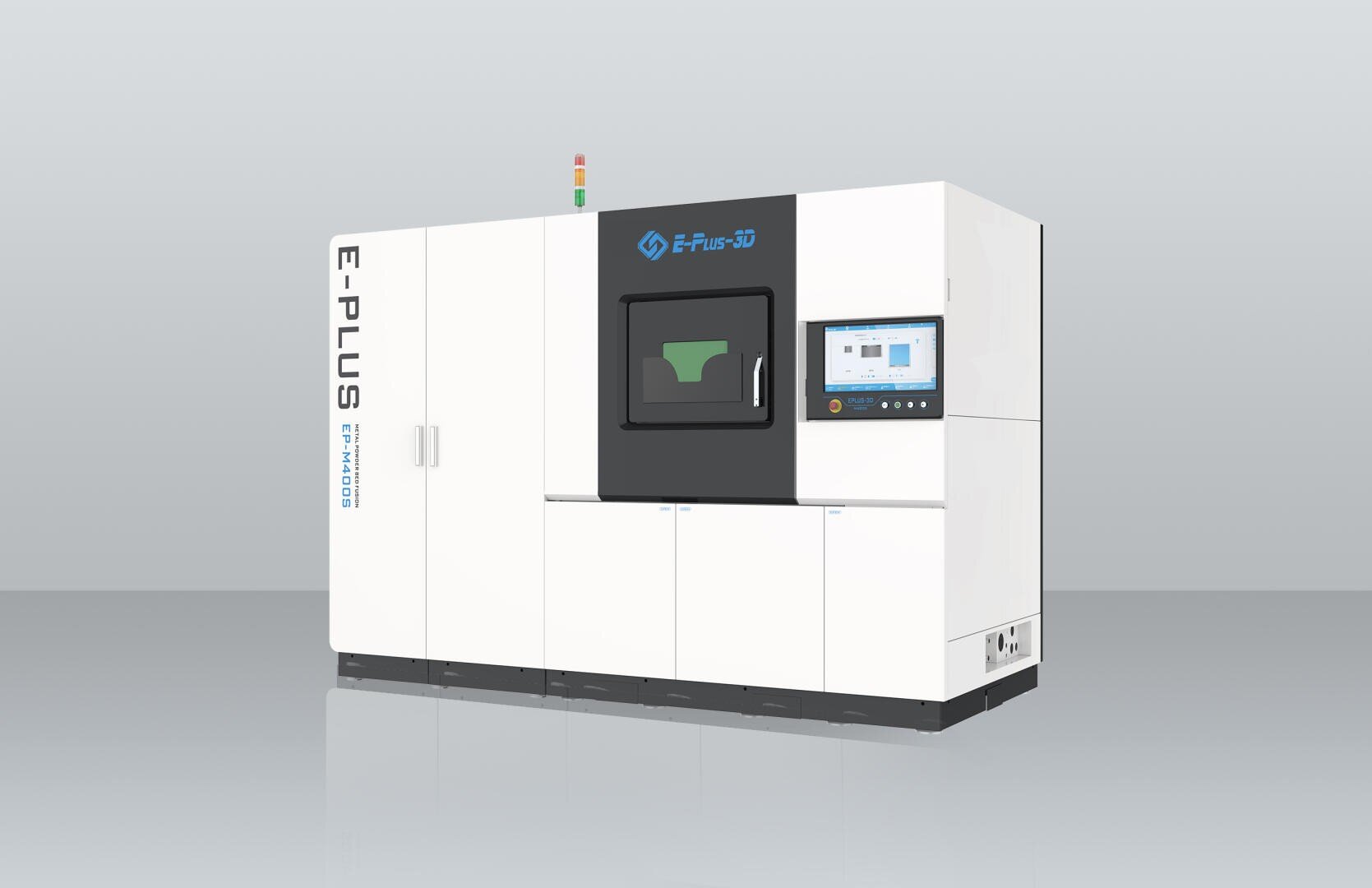

EP-M400S-Large size & high productivity & cost-effective Metal PBF System

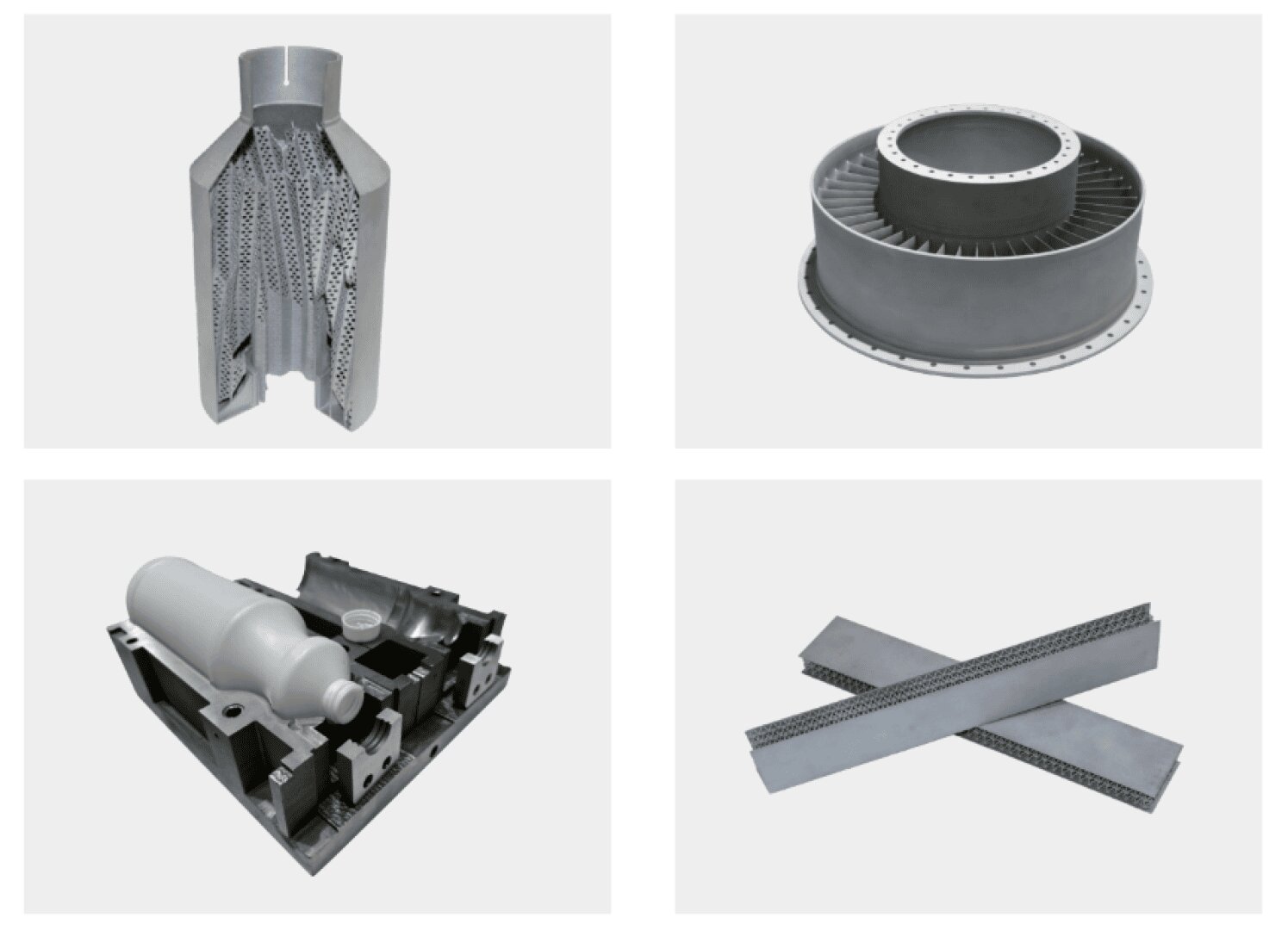

EP-M400S is suitable for the direct manufacturing of large-size, high-precision, high-performance components in aerospace, automotive, energy, machinery, tooling, healthcare sectors.

EP-M400S is available in four configurations: single, dual, triple and quad laser, offering the flexibility to print materials such as titanium alloy, aluminum alloy, nickel-based alloys, maraging steel, stainless steel, cobalt chrome and other materials.

By years of dedication, Eplus3D have built a global team of 400+ dedicated colleagues and Installed 1000+ metal printers at customer sites, 10% of which are in Europe. Eplus3D is committed to providing financially viable AM solutions and delivering the best ROI. The main ROI drives in AM machines are material waste reduction, machine uptime and productivity.

EP-M400S: Made for Efficiency

With a build volume up to 400 x 400 x 450 mm, EP-M400S is equipped with 4 Lasers and a permanent multi-material filter system. Combined with its bi-directional recoating configuration, EP-M400S significantly reduces material waste, maximizes machine uptime, and enhances productivity.

Additionally, the EP-M400S automated closed-loop system benefits our partners by enabling no contact with powder, no powder handling, no regular filter changes, and minimal cooldown time compared to the competition. Furthermore, it improves process automation in the long term.