3D printing for perfect rubber and silicone parts

There are many good reasons why elastic materials are used: to achieve a specific function, a special feel or an unusual appearance to name just a few – 3D printing helps in a fast and precise way to manufacture components made of silicone and rubber.

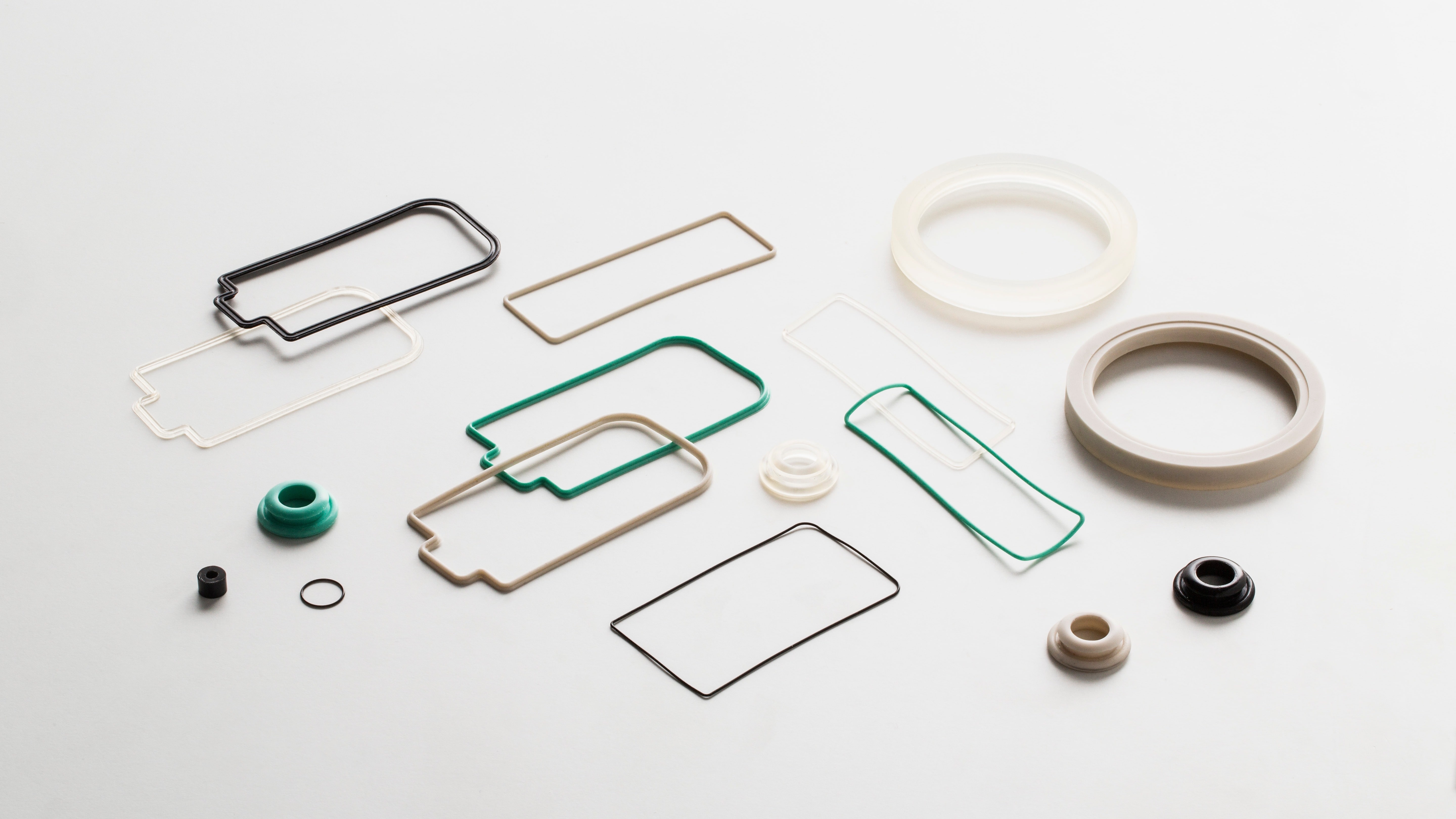

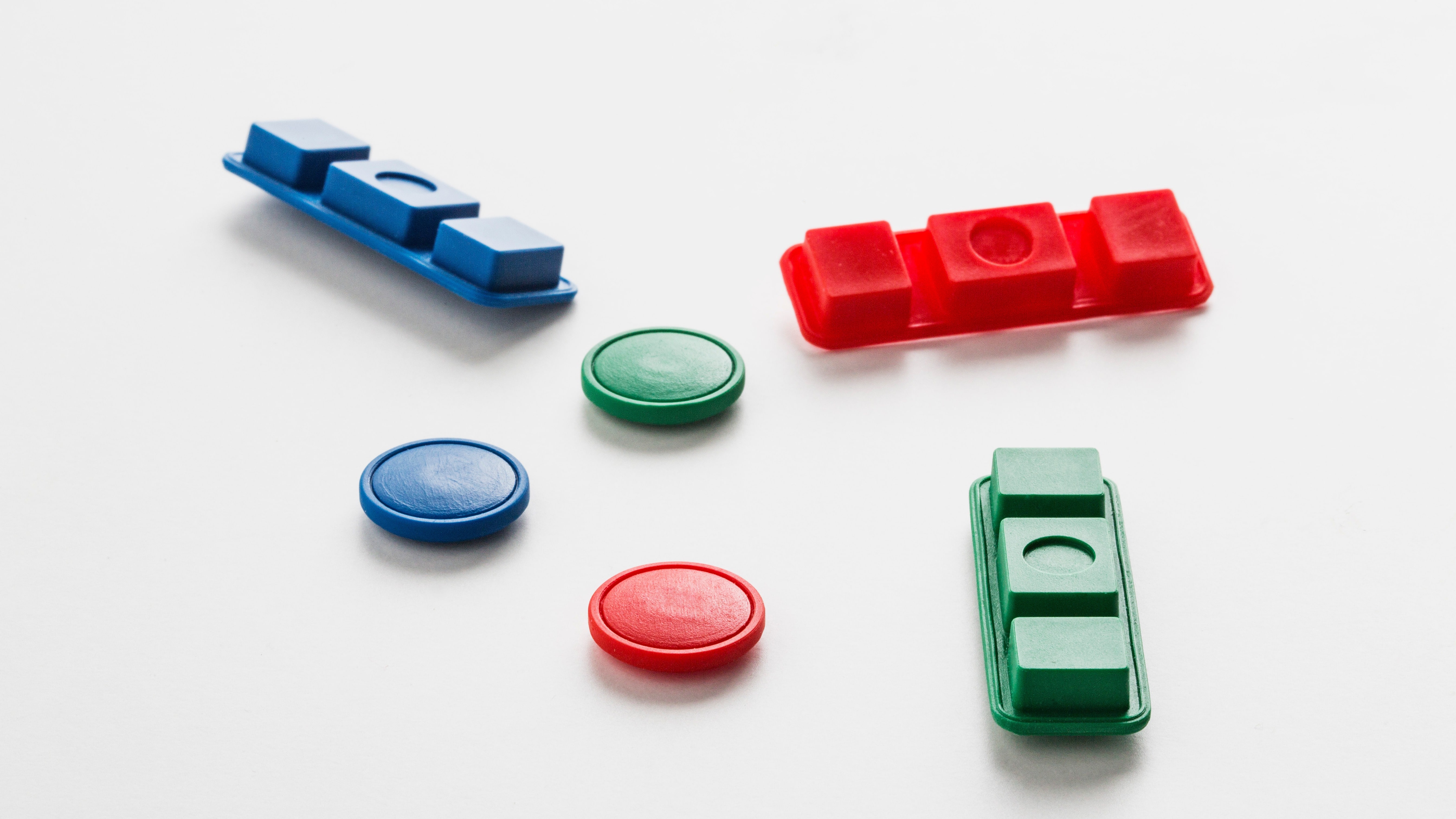

Gaskets, lines, operating elements, diaphragms, hoses, storage surfaces and much more – the applications for elastomer components are manifold. Before products go into series production, they must be developed and tested. Choices must be made between different variants. A single prototype is often not sufficient for this – many identical parts are needed.

And of course, time and costs are important factors: “We are now in a position to deliver functional parts within just four days,” says 1zu1's Managing Director Hannes Hämmerle. Previously, the lead time was between 10 and 15 days. The process has been redefined 1zu1 using 3D printing. The new procedure has now become the standard: “We have already produced over 1000 different geometries,” says Hannes Hämmerle. In view of the ever-shorter innovation cycles and increasing competition, this represents “an invaluable advantage”.

Silicone or rubber

1zu1 manufactures elastic parts from silicone or rubber. Silicone parts are available in almost any desired color. The rigidity ranges from Shore A 10 – comparable to the consistency of a fruit gum – to Shore A 70, which roughly corresponds to the hardness of a car tire. A wall thickness of just half

a millimeter allows intricate detailing. The resulting parts are also airtight and waterproof. 1zu1 special silicones for extra dimensional stability can withstand temperatures of up to 250 degrees Celsius and are food-safe.

3D printing opens up new, previously undreamed-of possibilities. Take the next step into the future with us and be inspired by the wide variety of components on show at our stand at the AM Expo.