Artivion: Rapid solution for life-saving medical technology - 10,000 pieces in constant quality

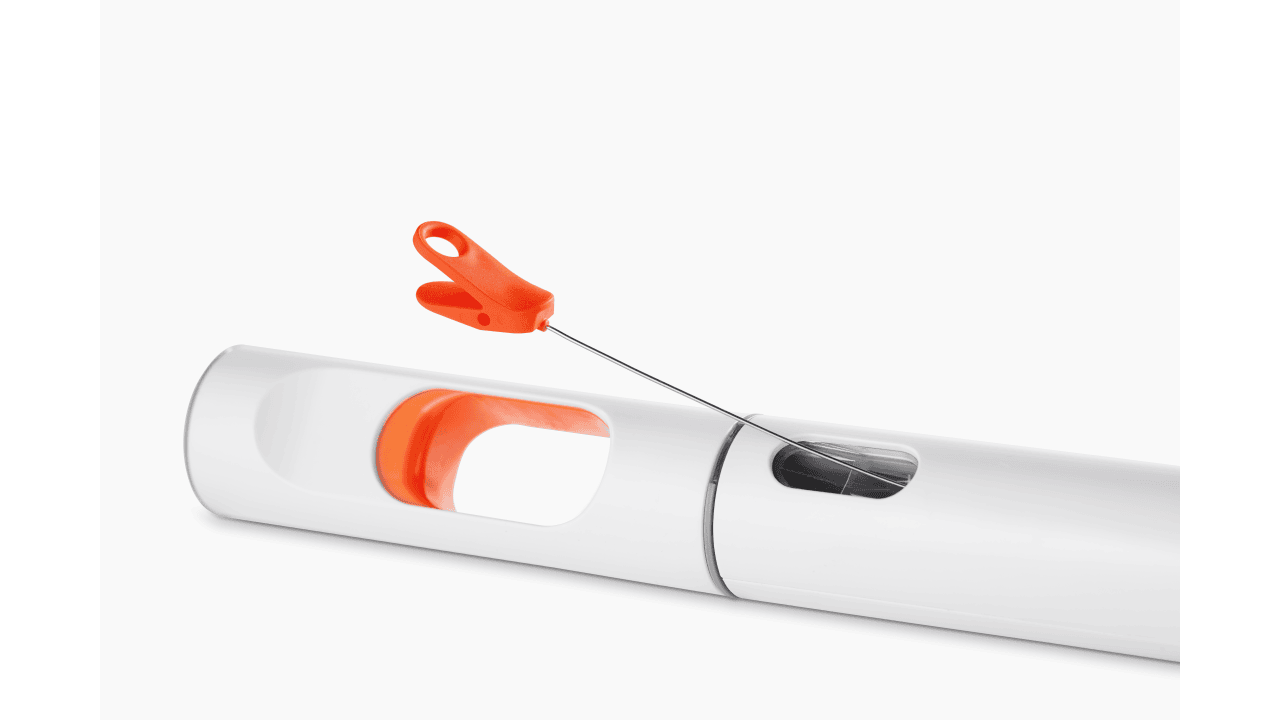

Artivion is a “hidden champion” on account of its vascular prostheses and stent graft systems. 1zu1 was involved at every step from development to series production of the latest generation of Artivion’s “E-vita Open Neo” hybrid stent graft system. Injection molding production in the cleanroom.

In 2017, the medical technology company JOTEC, originally founded in 2000, was acquired by the US-based group CryoLife and rebranded under the name Artivion in early 2022. The new name is derived from the words “aorta”, “innovation”, and “vision”. The company, which specializes in innovative technologies for the treatment of aortic diseases, currently employs around 500 people at its site in southern Germany – a number that is steadily rising. During development of the company’s latest disposable aortic arch replacement system, 1zu1 contributed a complete assembly consisting of production-ready plastic parts. This was manufactured following an intensive consultation phase that included high-precision prototypes.

The 3D-printed samples were created in spring 2018 and were quickly followed in the summer by the first injection-molded sample parts, which were produced using aluminum pilot molds. A few iterations later, the twelve series molds were ready for use and the first thousand stent graft delivery systems were produced – in 1zu1’s ISO Class 8 cleanroom. Artivion is already planning a second product line in early 2023, for which the delivery system will also be manufactured by 1zu1. In our interview, the two project coordinators at Artivion, Jakob Wojciechowski and Yannick Röcker, together with their counterparts at 1zu1 – project manager Dario Loss and head of Tooling Wolfgang Spiegel – recount this ideal journey from concept to market launch.

When and why was 1zu1 chosen as the series manufacturer?

Jakob Wojciechowski: We were looking for a quick solution for up to 1,500 units per year and 1zu1 was able to provide this through a combination of aluminum molds and cleanroom production.

Yannick Röcker: Of course, we were taking a risk because this manufacturing process was new to us. But the team at 1zu1 quickly convinced us with their careful advice and open communication. Our quality department also visited Dornbirn and was immediately impressed by the high level of their cleanroom equipment.

What are the advantages of injection molding with aluminum molds?

Wolfgang Spiegel: We can produce molds quickly and cost-effectively, and flexibly adapt them as needed. This accelerates development and market launch and gives our customers a competitive edge. With the final molds, we guarantee at least 10,000 units with consistent functionality and appearance, but we easily manage more than twice that number. Thanks to our in-house quality assurance process, we always know where we stand. So we can react quickly. As soon as the quality falls off, we offer a revision or a duplicate and request a new release. In addition to the speed advantage, this also pays off financially. At 10,000 units, the costs are about 25% lower compared to series production via conventional injection molding with steel molds.

How did you make the leap from prototype to series project?

Dario Loss: After a month of intensive consultation, the first 3D-printed parts followed. Another month later, the design was optimized and rapid tooling continued. Initial sampling of all molds was complete as early as the summer. After a few optimizations, the whole assembly consisting of twelve components was ready for series production. In parallel, we created the detailed documentation for the series process. The time frame from initial sampling to the validation phase and then series production was just 16 months – the blink of an eye in the medical technology sector.

Wolfgang Spiegel: We’re right up there with the leaders. We contribute our own experience and expertise to ensure the design is suitable for injection molding, offer an extensive range of materials, and implement changes quickly. In this way, we shorten the journey to the end goal.

What were the design and manufacturing challenges?

Jakob Wojciechowski: With the aluminum molds, the tolerances are sometimes larger and burrs are an issue. For medical products, there must be no sharp edges and no particles must come loose. And, of course, all the components need to match each other perfectly in terms of the color and dimensions, and create a visually pleasing whole.

What was the next step?

Jakob Wojciechowski: We checked the samples’ dimensions and tested them in the assembled state. The 3D scan 1zu1 provided was a big help here. It allowed us to compare the samples to the CAD data and easily spot any deviations. We then sent our requirements back to 1zu1 for a speedy implementation. Together, we quickly and smoothly resolved every issue step by step and readjusted the molds.

Dario Loss: Careful planning always pays off in the end. It’s often worthwhile adding an extra round of checks and coordinating the results again with our professional staff – especially given the stringent requirements for medical technology. So it’s a great advantage that we can respond so quickly and flexibly by making minute adjustments to the wall thickness or other geometric details, such as the concave shapes. We can deliver a fresh batch of testable components in just three to four weeks. That wouldn’t be feasible with conventional injection molding.

How would you characterize the collaboration?

Jakob Wojciechowski: Even the first meeting was very pleasant and constructive. The timelines with milestones for each element were especially helpful. This meant we always had a clear overview of the project status.

Wolfgang Spiegel: Courage and mutual trust. Customers who stick with us all the way to series production will be rewarded with the desired results in the end. From the outset, we make time for the project and the customer on a personal level and are passionate about our work.

What are the next steps for Artivion und 1zu1?

Yannick Röcker: After this positive experience, the decision was made to also implement the follow-up project with 1zu1. We’re currently working on a second product line for the US market. Besides some optimizations, the orange components will be replaced by turquoise ones, the color of Artivion. The final 3D-printed prototypes are ready, and series production is scheduled to start in summer 2023.

Our interviewees: Jakob Wojciechowski and Yannick Röcker are development engineers at Artivion (formerly JOTEC). Dario Loss, project manager for toolmaking and injection molding, and Wolfgang Spiegel, head of Tooling, are in charge of these joint projects at 1zu1. The interview was conducted by Joshua Köb, photos by Darko Todorovic.

* A stent graft is a combination of a stabilizing wire mesh and a plastic artificial blood vessel.