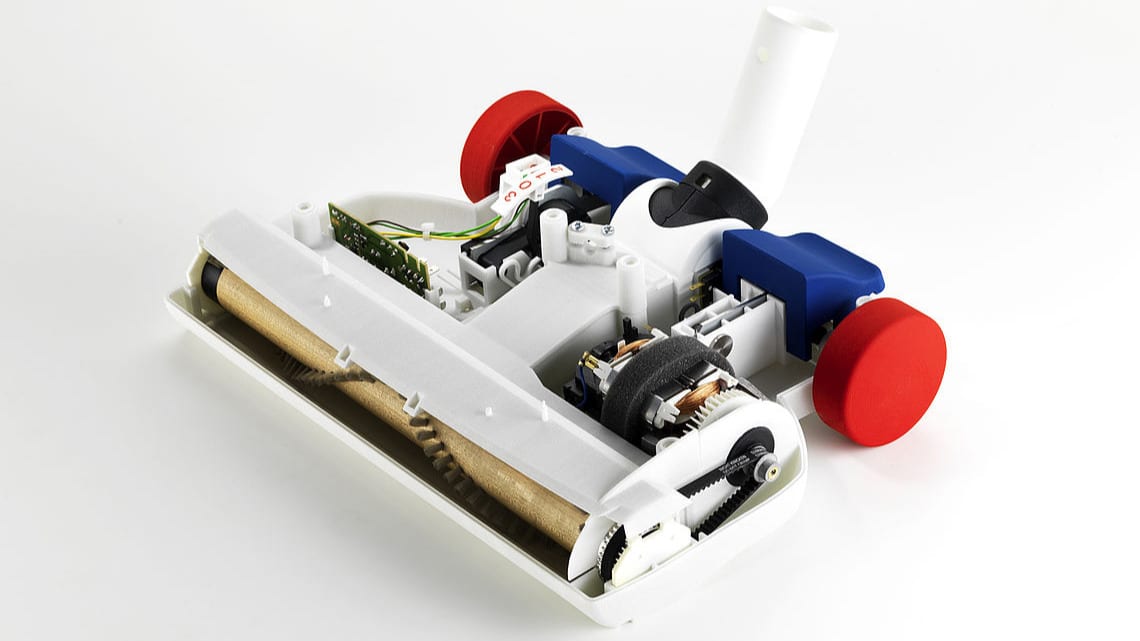

Motorised vacuum cleaner nozzle: Accurate in every detail

New development of a vacuum cleaner nozzle, which could already be thoroughly testet and optimised during the prototype phase. A distinct benefit of 3D-Printing: Short time-to-market provides competitive advantages.

The customer required a prototype that could already be thoroughly tested and optimized during the prototype phase.

Functional tests passed

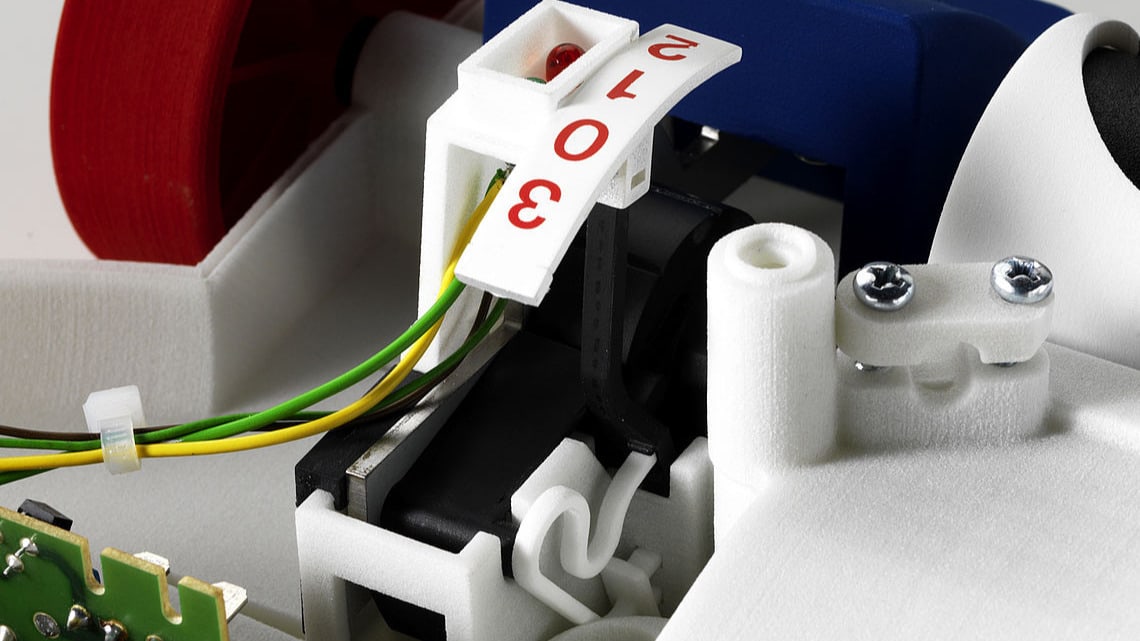

In the polyamide prototype, the electrical components were pre-installed and the spring which has an importent role, was sintered to full spring functionality. An advantage of the laser sintering process ist, that the components easily withstand long-term tests.

The base shells and covers had to meet high demands during the tests. This could be achieved thanks to glass-reinforced polyamide. Stiffnes, strength and dimensional accuracy were required. A nice side effect: the components remain perfectly in shape for joining together with other components.

Color known

The open-pore surfaces of the laser sintered parts allow color preferences of your choice. Everything from the RAL color scale can be realised. In the vacuum cleaner nozzle we coulored the wheels in strong red, the rear buttons in beautiful blue and the hose connection in uncompromising black.

Robustness proved

In the meantime, the nozzle elegantly cleans carpets and hard grounds in many homes.