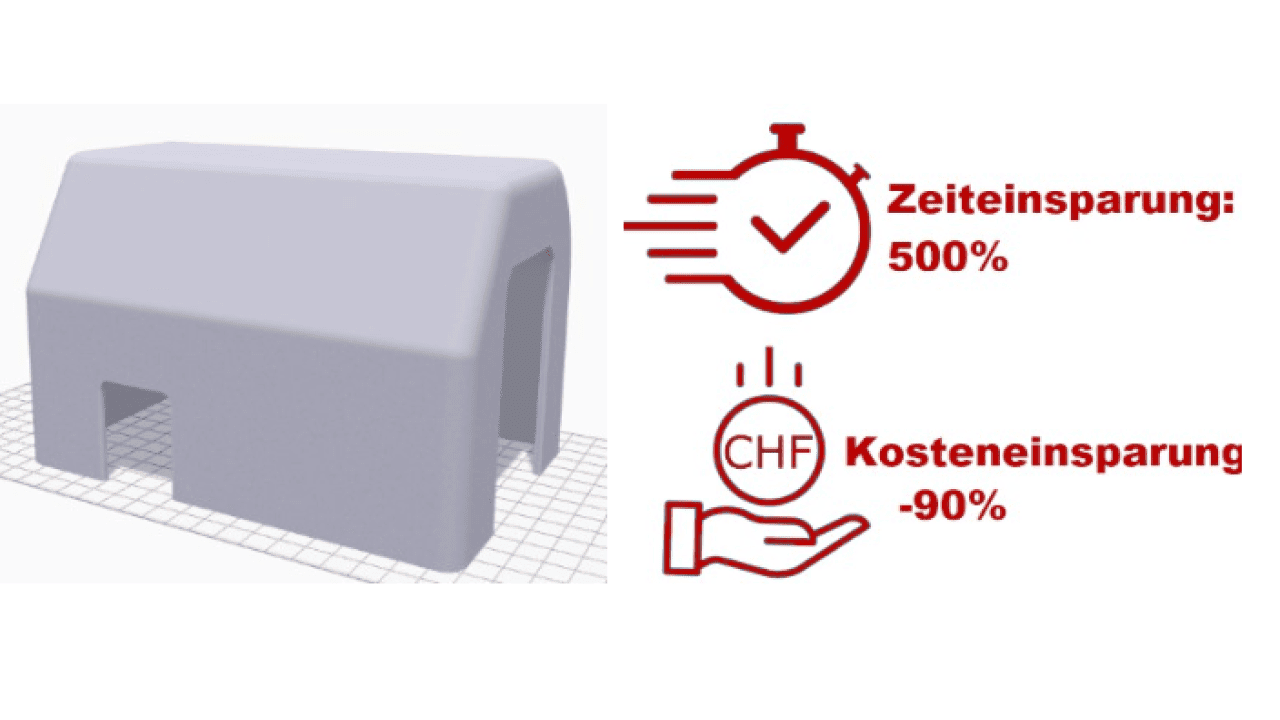

Practical example of how you can really save costs in 3D printing!

Challenge: There are not many printing methods with the UL94V0 property in black. Costs for SLS processes for this material/geometry were too high. Approach: Test UL94V0 filament to realize this task in the FDM printing process and use new High Speed Printers.

Implementation:

6 different filaments were tested until a usable filament was found that met UL94V0 and also had enough layer adhesion between the layers. (This is usually not stated anywhere in the material data sheets).

Test methods used:

Mechanical tests Flammability test Optimization measures used in printing: Slicer with organic support structures Printer with installation chamber temperature >70 °C Printers with compensation of the resonance on the axes = higher printing speed with the same quality.

Savings achieved compared to standard printing processes: Material costs -90% Printing time savings: 500%.