3D printer for technical ceramics

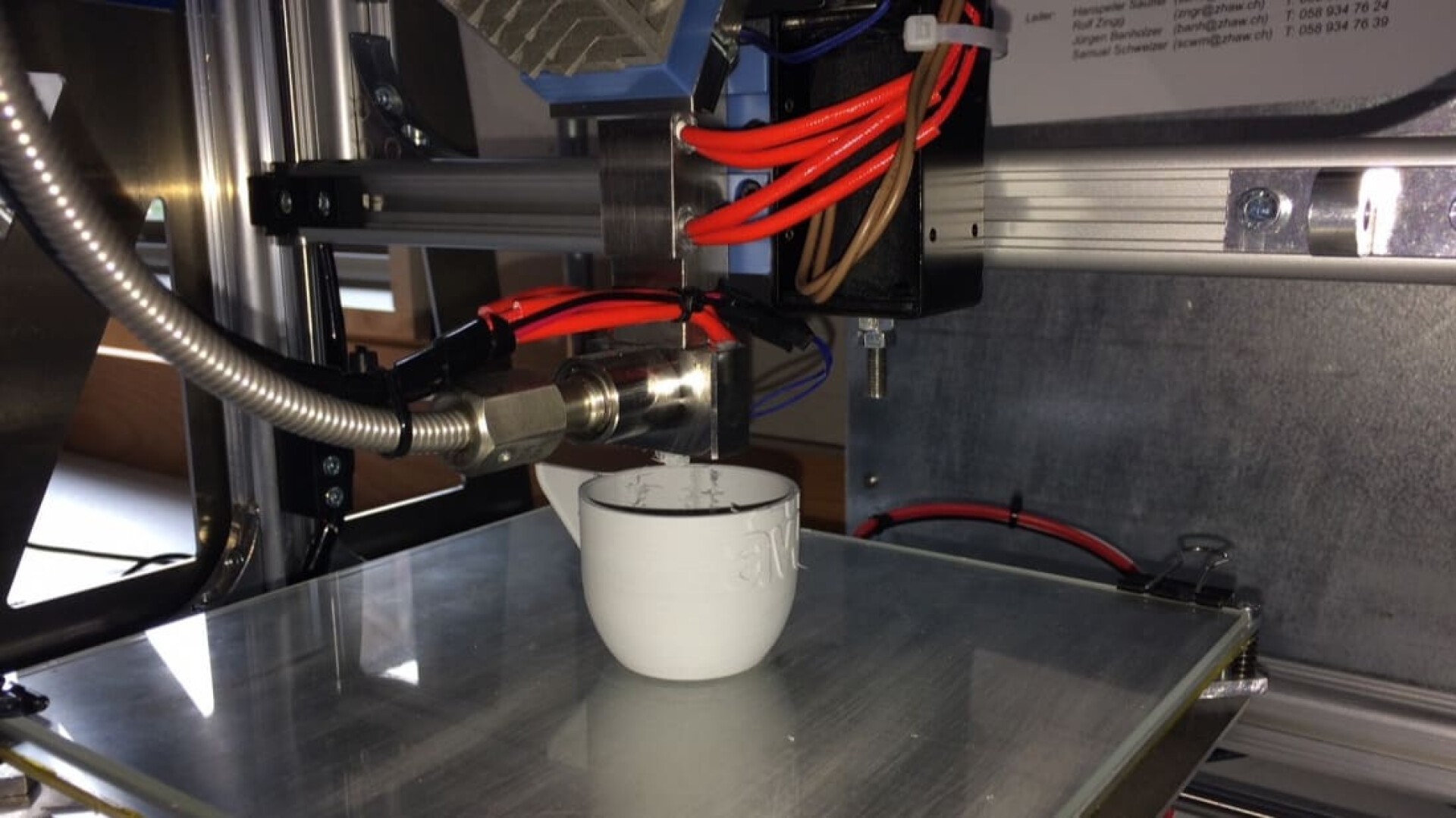

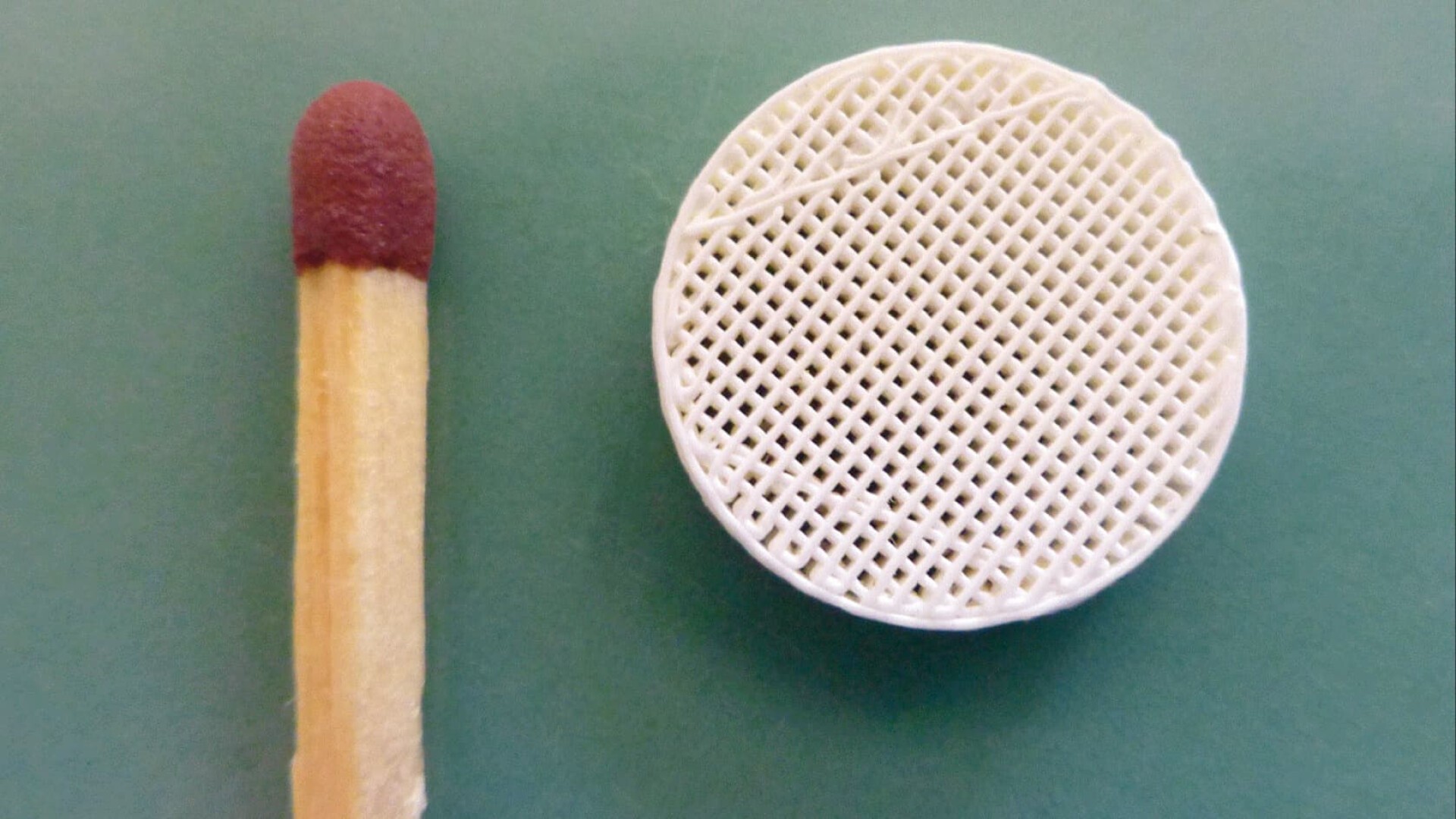

3D printed ceramic components are in demand on the market, but there are only a few 3D printers that meet the high component requirements. Therefore, ZHAW developed a prototype of a 3D ceramic printer based on microextrusion with subsequent sintering.

Today, there is a wide range of 3D printers for additive production of plastic and metal parts. Ceramic components are also in demand on the market, but there are only a few 3D printers that meet the high component requirements. In an interdisciplinary development project, a prototype of a 3D ceramic printer was developed at the ZHAW with the participation of the ZPP (Centre for Product and Process Development), IMPE (Institute of Material and Process Engineering) and IMS (Institute for Mechatronic Systems).

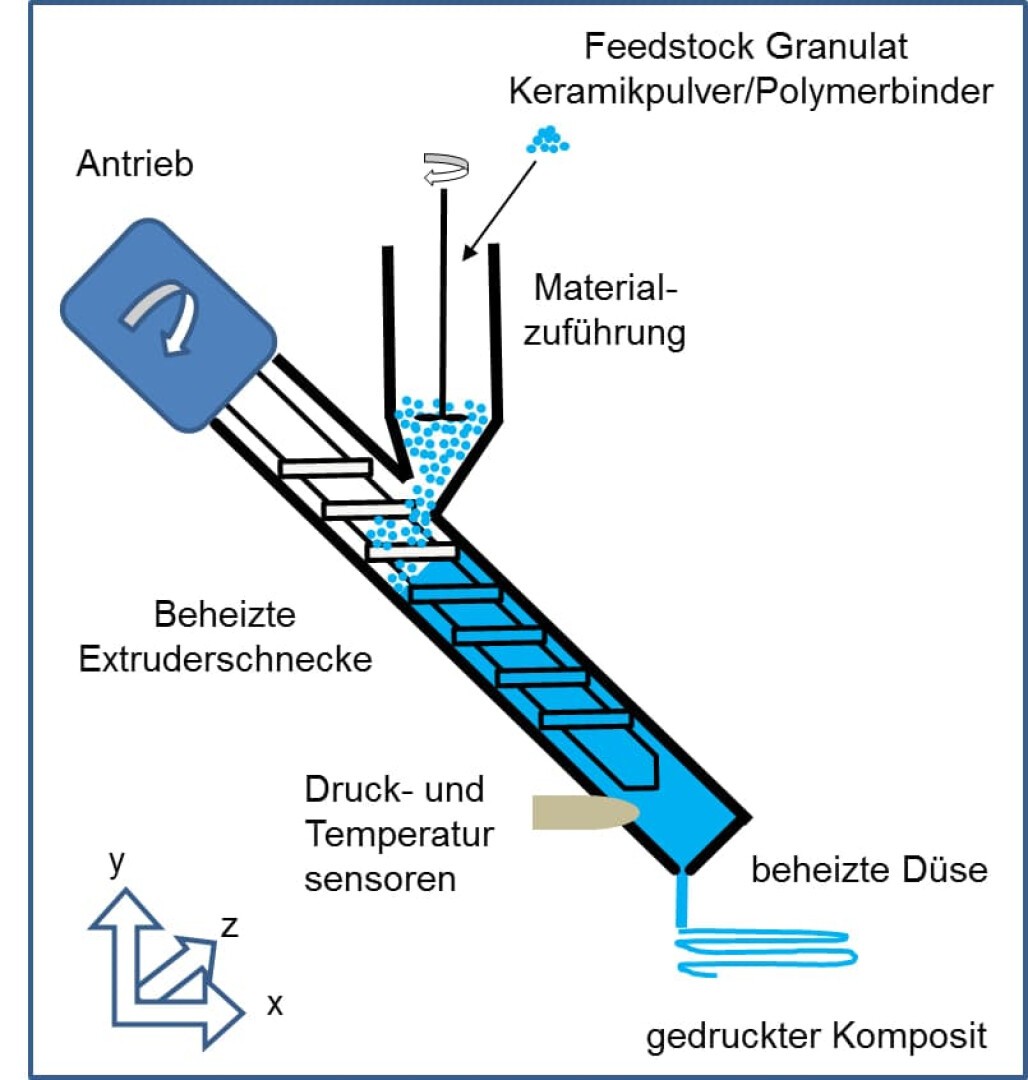

The printing principle is based on a combination of micro-extrusion and FDM Fused Deposition Modeling.

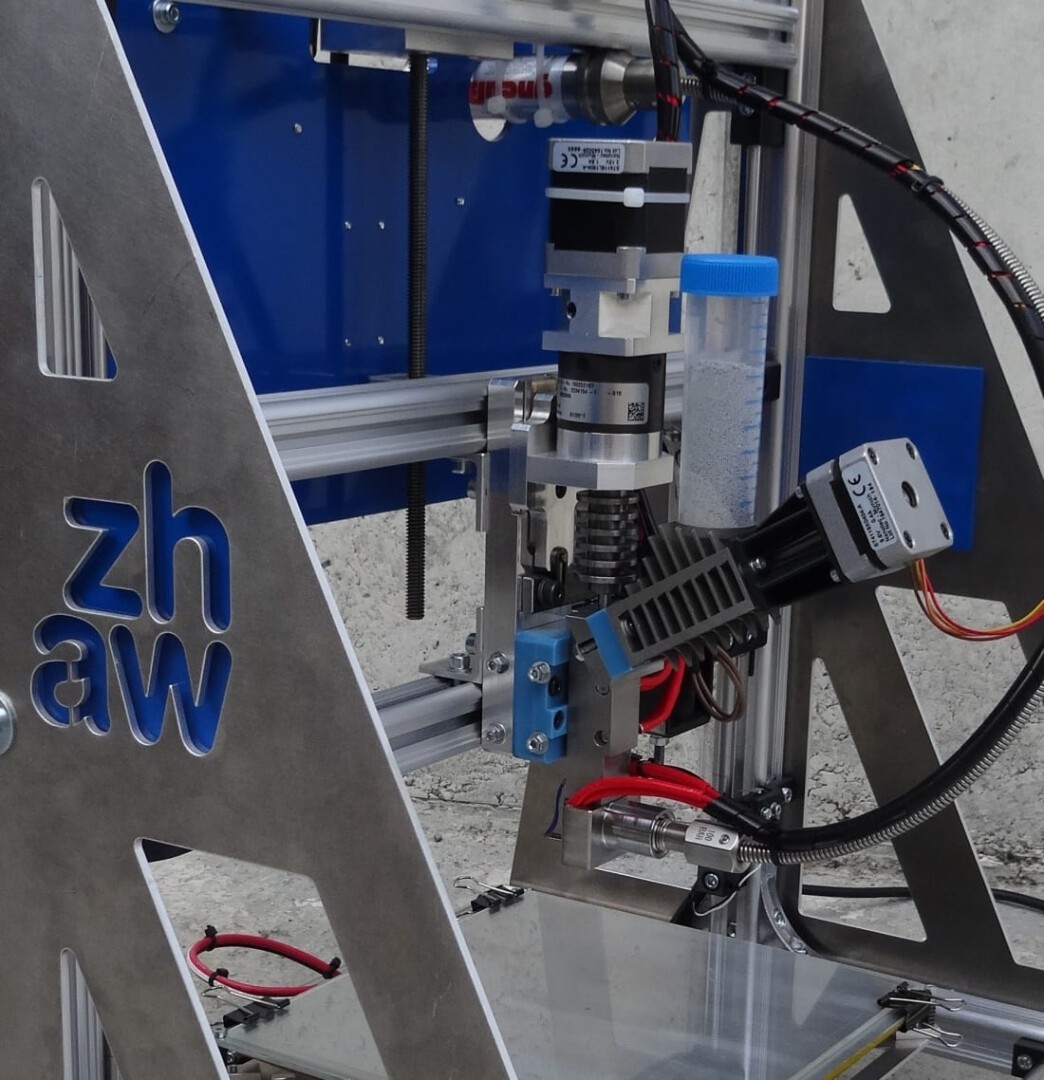

Constructive work (ZPP)

Redesign and construction of a printhead

Integration in a 3-axis system

Control, regulation, programming (IMS)

Controlling the printer

Implementation heating, power transmission, pressure control

Material development (IMPE)

Preparation of Al2O3, ZrO2 and SiC composites

Print parameter studies (p, T, V, ...)

Debinding / sintering procedure for ceramics production