Al2139 AM – High Performance from the Powder Bed

High-strength, temperature-resistant, and made for 3D printing: the alloy for demanding lightweight applications. Learn how we at Unlimital turn this material into performance.

EOS Aluminium Al2139 AM is setting new standards in lightweight design for additive metal manufacturing. Based on a high-strength 2000-series aluminium alloy, this material was developed specifically for the DMLS process (Direct Metal Laser Sintering) – combining high strength, thermal stability, and efficient post-processing in a single material.

In its heat-treated T4 condition, Al2139 AM achieves a yield strength of around 460 MPa and a tensile strength of up to 520 MPa. Compared to common AM alloys such as AlSi10Mg, Al2139 AM offers significant performance advantages, especially in applications operating between 50 °C and 200 °C.

Another key benefit is the simplified heat treatment: solution annealing, quenching, and natural aging are all it takes. This eliminates complex post-aging cycles and reduces active oven time by up to 88 %, making it highly attractive for serial production.

Versatile Applications

Al2139 AM is ideal for industries and use cases that demand lightweight construction, mechanical strength, and thermal resistance:

-

Lightweight Structures

Whether complex brackets, housings, or load-bearing parts – Al2139 AM enables high-strength, weight-optimized components. Perfect for mechanical engineering, robotics, or UAV systems. -

Aerospace & Aviation

Reducing part weight and count while enabling design freedom – ideal for structural components, functional mounts, or integrated cooling solutions. -

Defense Applications

Its robustness and thermal performance make this alloy a strong candidate for housings, heat sinks, and demanding structural elements. -

Cooling Applications

Additively manufactured components with internal channels or bionic geometries offer significantly improved thermal conductivity – ideal for power electronics and thermal management systems. -

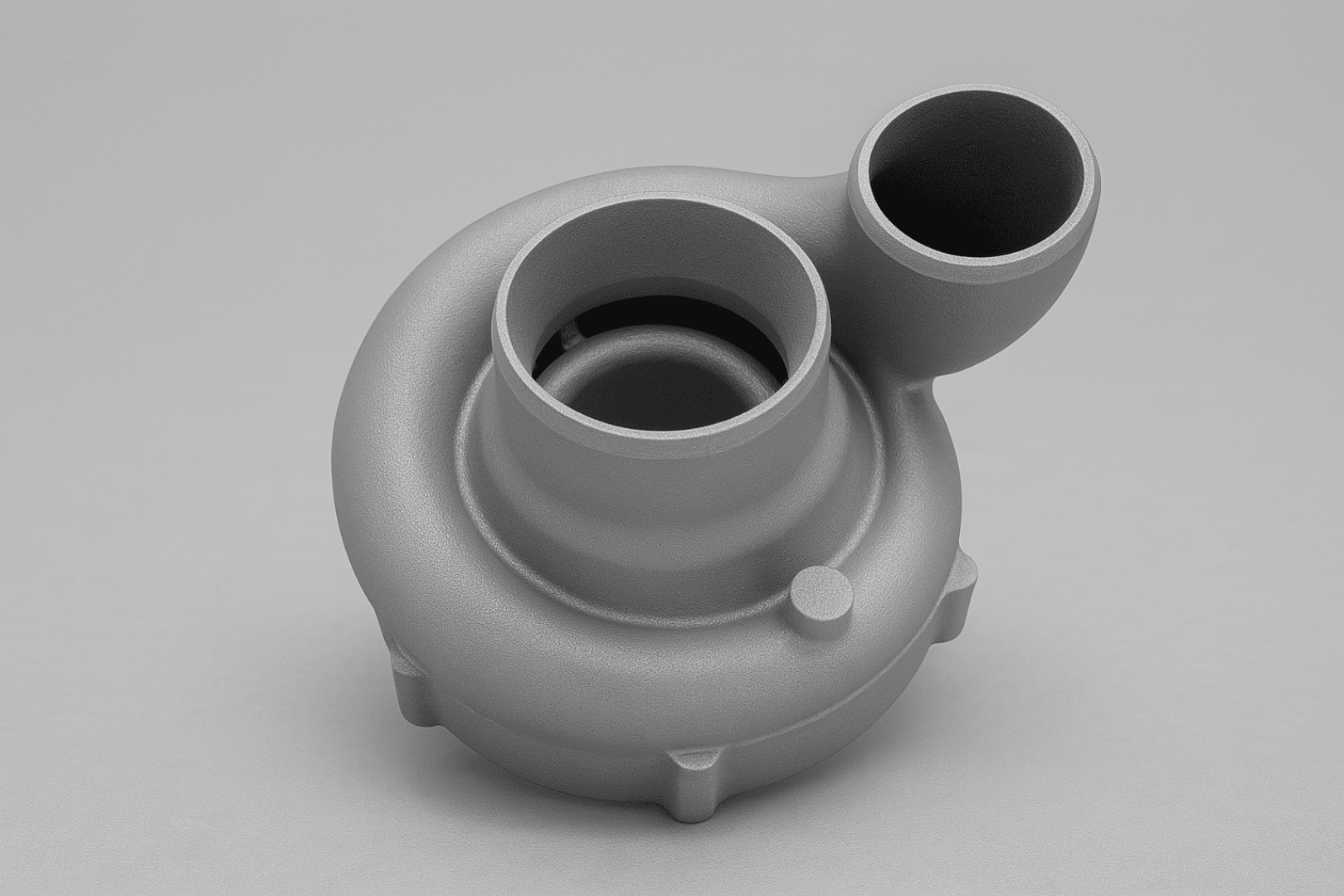

Motorsport

Al2139 AM is also used in high-performance racing – for example, in wheel carriers, brackets, or fluid-handling components that must be extremely strong and incredibly light.

Surface & Finish

Al2139 AM also proves its versatility in post-processing:

-

Vibratory finishing (tumbling) ensures smooth and consistent surfaces, reducing roughness and improving the tactile quality of parts.

-

Anodizing adds corrosion protection and allows for colored finishes – ideal for visible components with high standards in durability and aesthetics.

Performance Meets Process Efficiency

Al2139 AM delivers outstanding material performance paired with process efficiency – making it a strong choice for companies looking to push the limits of metal additive manufacturing.

At Unlimital, we bring this material to life:

From engineering consulting and topology optimization to the printing process, post-processing, and final assembly – efficient, precise, and forward-thinking.

👉 Interested in exploring Al2139 AM for your next project?

Let’s talk – we’re ready to turn your idea into metal.