CREAMELT® 3D Printing Filaments

CREAMELT® is a registered trademark of the Institute for Materials Engineering and Plastics Processing IWK of the OST - Eastern Switzerland University of Applied Sciences. We develop, produce and optimize filaments for Fused Filament Fabrication (FFF) 3D printing.

Customer-specific filament development

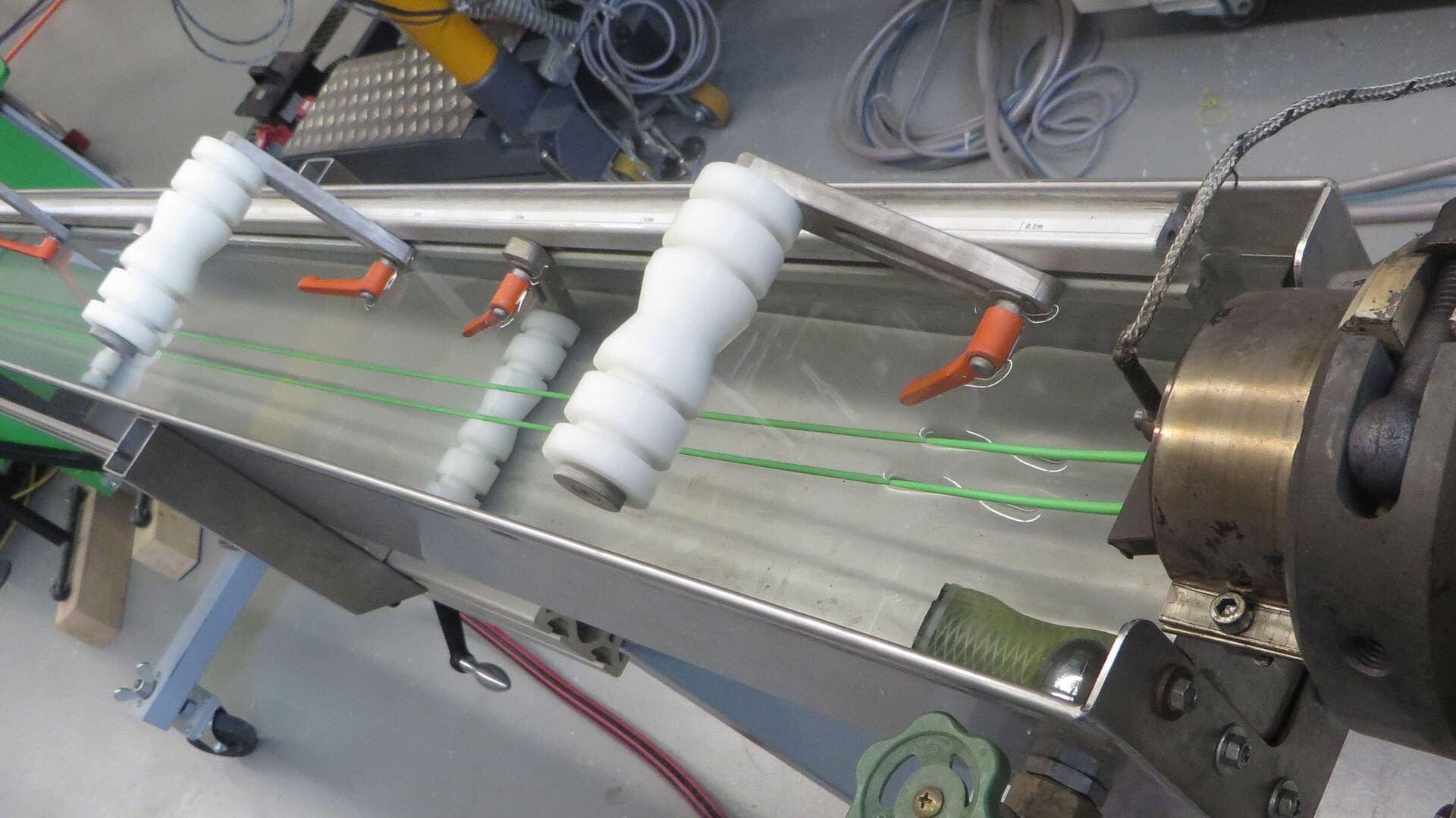

For new applications and special customer requirements, we use our knowledge of materials technology and plastics processing to develop new formulations and to adjust the desired material properties on our compounding line. All our filaments are then produced internally at our site in Rapperswil-Jona, Switzerland. The standard diameter of our filaments is 1.75+/-0.05 mm and 2.85+/-0.1 mm. The tolerances are continuously monitored via inline laser measurement. Diameters between 1 and 3 mm can also be realised on request. The filaments are wound directly onto spools at the end of our extrusion line. As standard, we offer spools with net weights of 750 g and 2.3 kg. Other dimensions are possible on customer request. Finally, all new filaments are tested on different 3D printers in our test lab. To evaluate the best process parameters, selected test objects are printed and evaluated with different settings. Our aim is to supply high-quality materials with good properties and high process capability for our customers' applications.

Current CREAMELT® filament portfolio

CREAMELT® PLA-HI: Impact-resistant PLA for technical applications

CREAMELT® PLA-HI is a bio-based 3D printing filament with high impact strength. It consists of PLA (Polylactic Acid), a biopolymer based on natural resources, which has been additionally modified with additives. It has interesting mechanical properties, good layer adhesion and is easy to print with a high achievable precision.

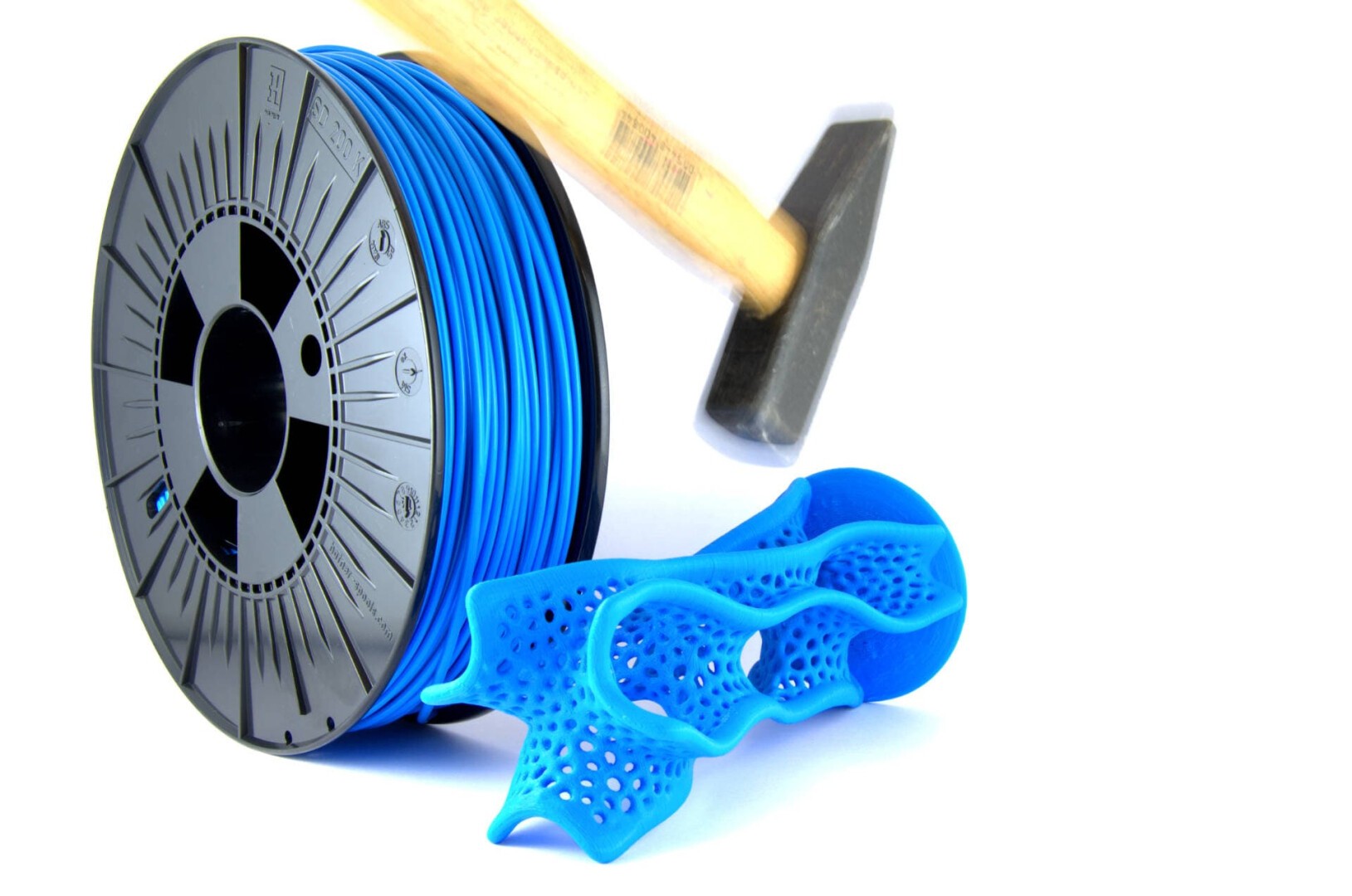

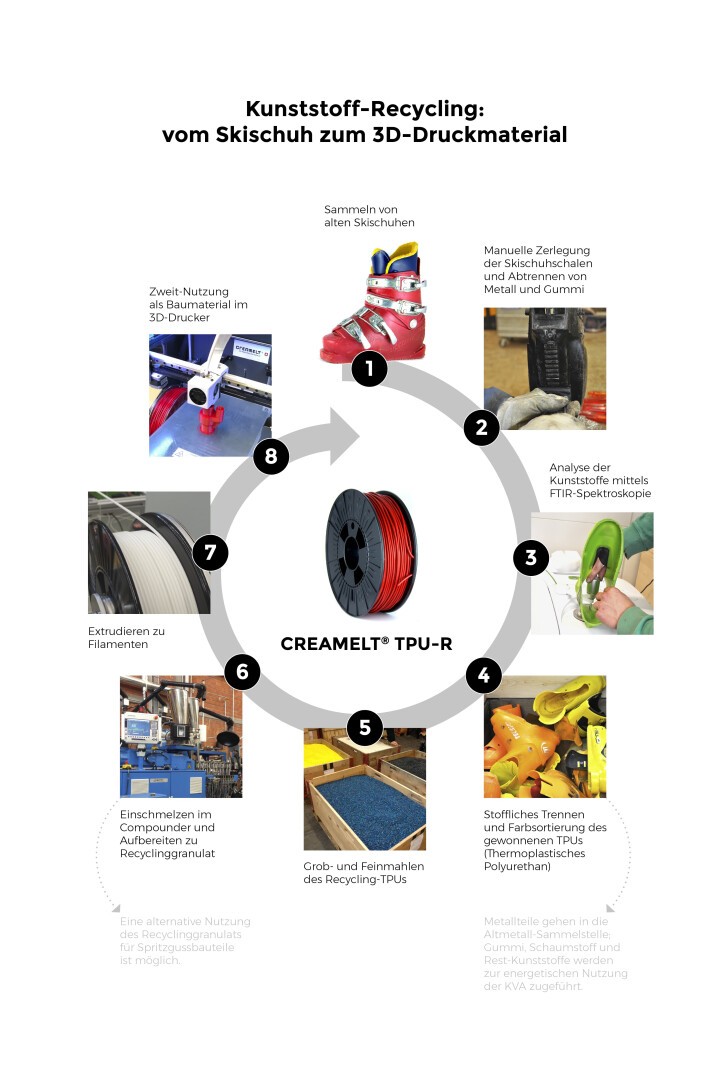

CREAMELT® TPU-R: Flexible recycled filament from old ski boots

CREAMELT® TPU-R is an elastic filament for 3D printers, that is made from 100% recycled ski boots. For the the ski boot material, we work closely with the ARGO workshop in Davos, where people with disabilities recycle old ski boots. After chemical analysis and colour sorting, the collected plastic is shredded, remelted and extruded into new 3D printing filaments.

CREAMELT® TPU-R enables flexible objects to be printed from recycled material, and is therefore a sustainable alternative to virgin material.

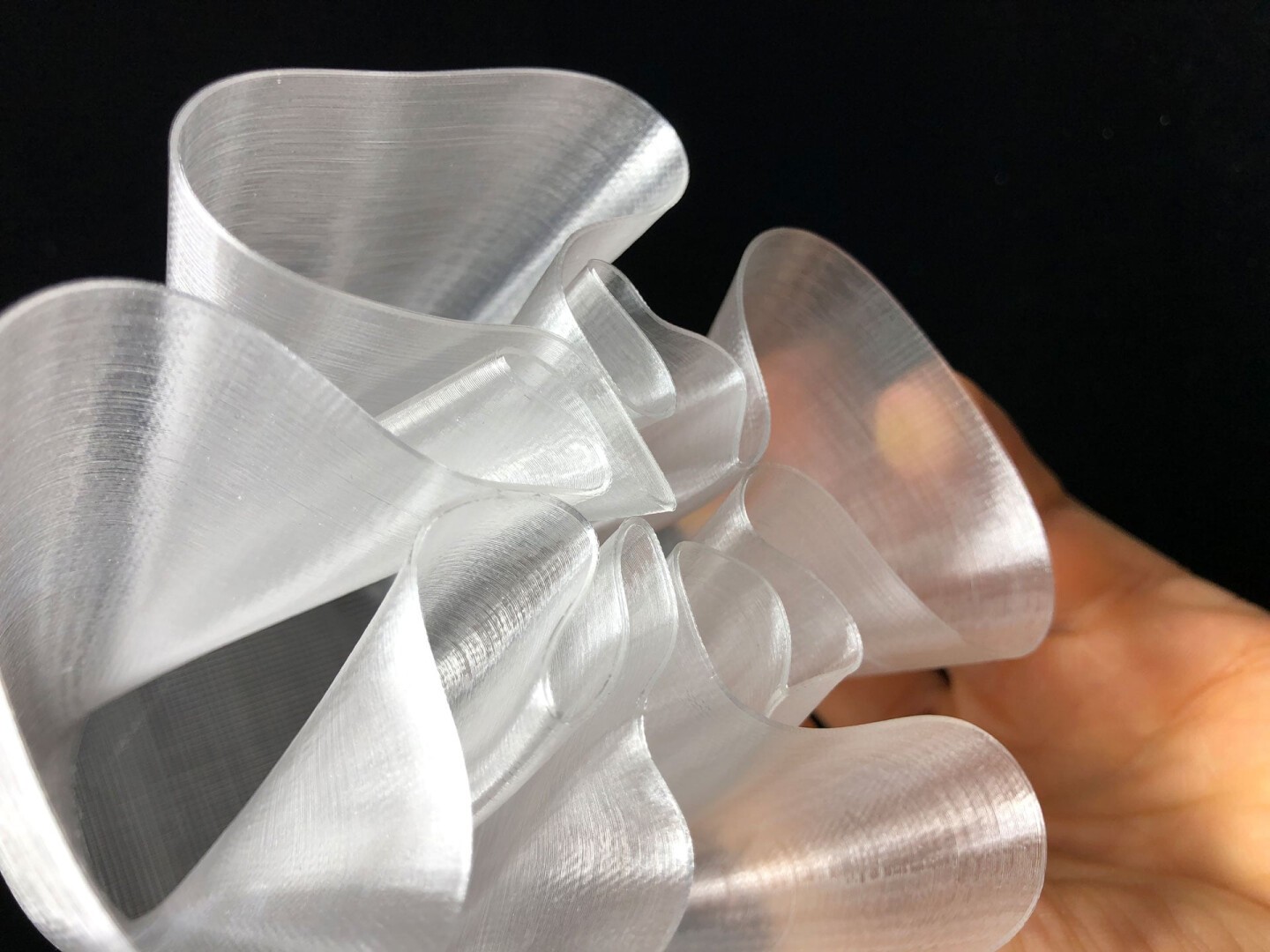

CREAMELT® COC: Highly transparent and chemically resistant

CREAMELT® COC is a transparent filament made of Cyclic Olefin Copolymer (COC), which offers excellent properties: Biocompatibility, high transparency, very low water absorption, good barrier properties, excellent resistance to acids and alkalis as well as to many sterilisation processes. The amorphous polymer has a very good process stability and can be processed on any standard FFF 3D printer.

Coming soon: CREAMELT® rPET fifty

CREAMELT® rPET fifty: SUSTAINABLE FILAMENT 100% MADE FROM RECYCLED PET

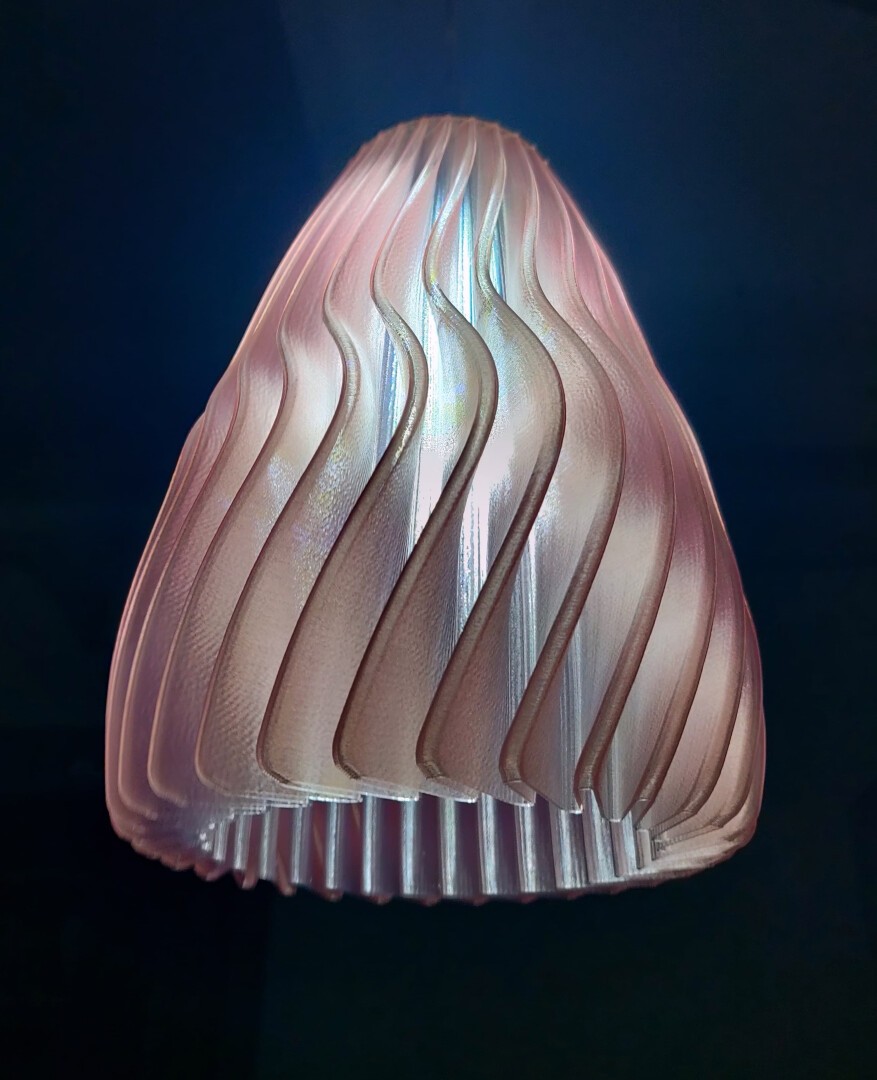

CREAMELT® rPET fifty is a filament made from 100% recycled PET (polyethylene terephthalate). It consists of 50% industrial multilayer PET-G/PET and 50% ocean-bound PET waste from #tide.

rPET fifty gives you the ability to design and print durable parts with great chemical and heat resistance made from recycled materials and is a sustainable alternative to virgin material. Its distinctive appearance is great for interior design objects such as lampshades or vases.

Webshop and more informations

Further information about our products and laboratory equipment can be accessed via our webshop www.creamelt.com. If you are interested in our filaments or in a collaboration in the field of filament development, you are also welcome to contact us via the contact coordinates listed on the website.