Ecoparts AG continues to invest in future-oriented production technology

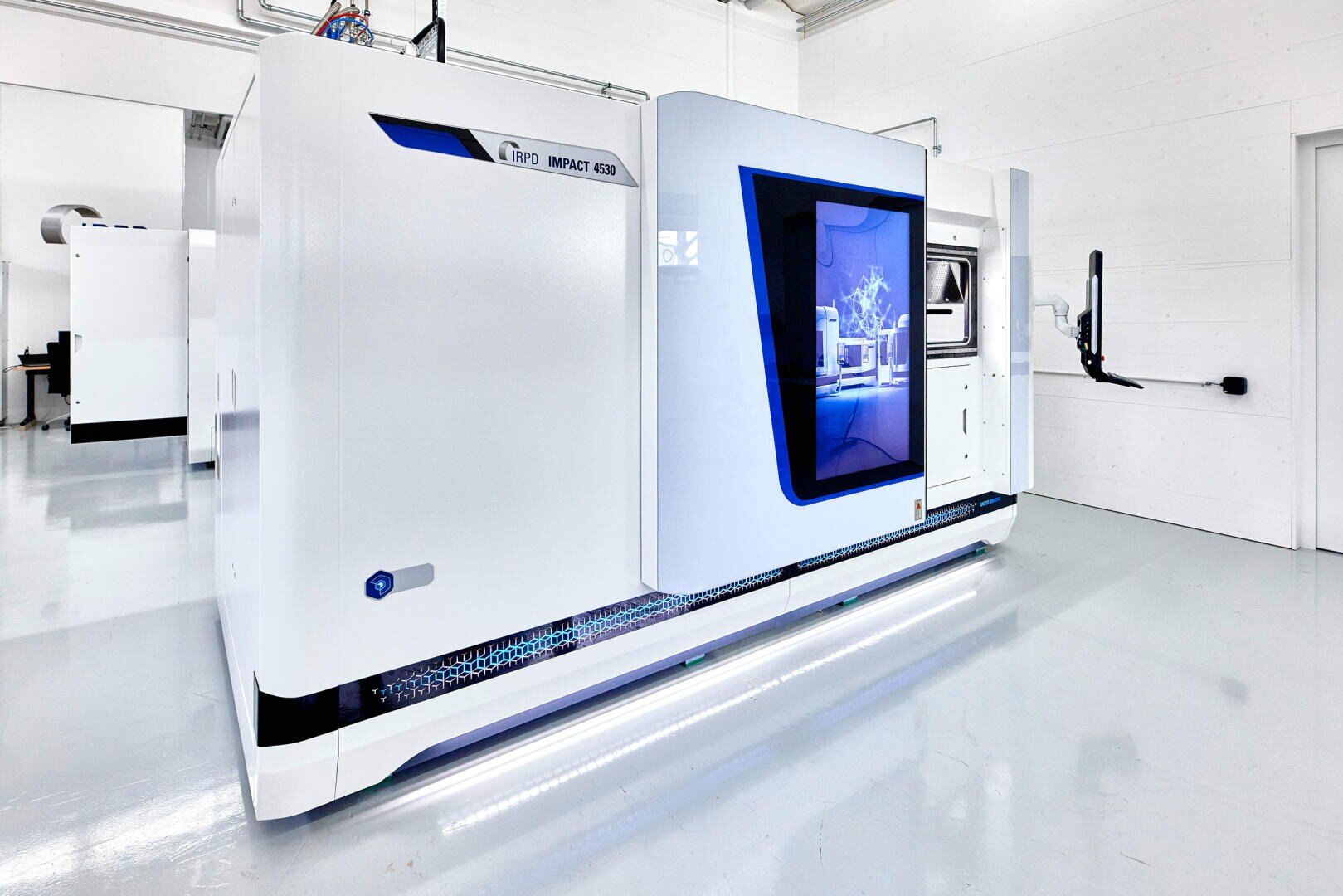

Ecoparts AG has ushered in a new era of additive manufacturing: with the purchase of the IMPACT 4530, a state-of-the-art 3D metal printer "Made in Switzerland" by IRPD from St. Gallen, the company is focusing on maximum productivity, flexibility and future-proofing.

The strategic advantages for Ecoparts include the expansion of its product range, as the new machine will enable it to offer larger components and series. It also strengthens the company's technological leadership, as the investment consolidates its position as an innovation leader in the field of additive manufacturing. Furthermore, the local partnership underlines the company's commitment to sustainable production and Swiss quality.

Daniel Kündig, Co-Founder and Head of Technology, and Adrian Helbling, Co-Founder and Head of Marketing & Sales, see the IMPACT 4530 as a future-proof solution that meets the increasing demands of the industry.

The technical highlights of the IMPACT 4530 include an building space of 450 × 300 × 400 mm, which is ideal for the production of larger components from a single piece. The laser power is made possible by four fiber lasers with 1,000 watts each, resulting in high build rates. The modular powder and build container system allows quick changes between materials and jobs.

The Ecoparts-IRPD collaboration represents a strategic milestone. Stefan Lang, CEO of IRPD, emphasizes: "With Ecoparts as the market leader in the service sector, we have found the ideal partner. Together, we will continue to develop the system and adapt it to market requirements."

Enthusiasm is also high at Ecoparts. Denis Forster, CEO, emphasizes:

"The IMPACT offers us the opportunity to achieve very high productivity and produce parts in a wide variety of alloys." The new machine will be in productive use from mid-October 2025. Feel free to visit us in Hinwil.