Leak-Free, Liquid-Cooled Heat Sinks

CoolestDC launches highly customizable, leak-free in-server liquid cooling solutions to accelerate green data center initiatives—powered by EOS additive manufacturing technologies.

The data center sector is experiencing rapid growth—driven by cloud applications, digitalization, the Internet of Things, and 4G/5G edge computing. To meet increasing demands for performance and sustainability, CoolestDC turned to the advanced additive manufacturing (AM) technology from EOS.

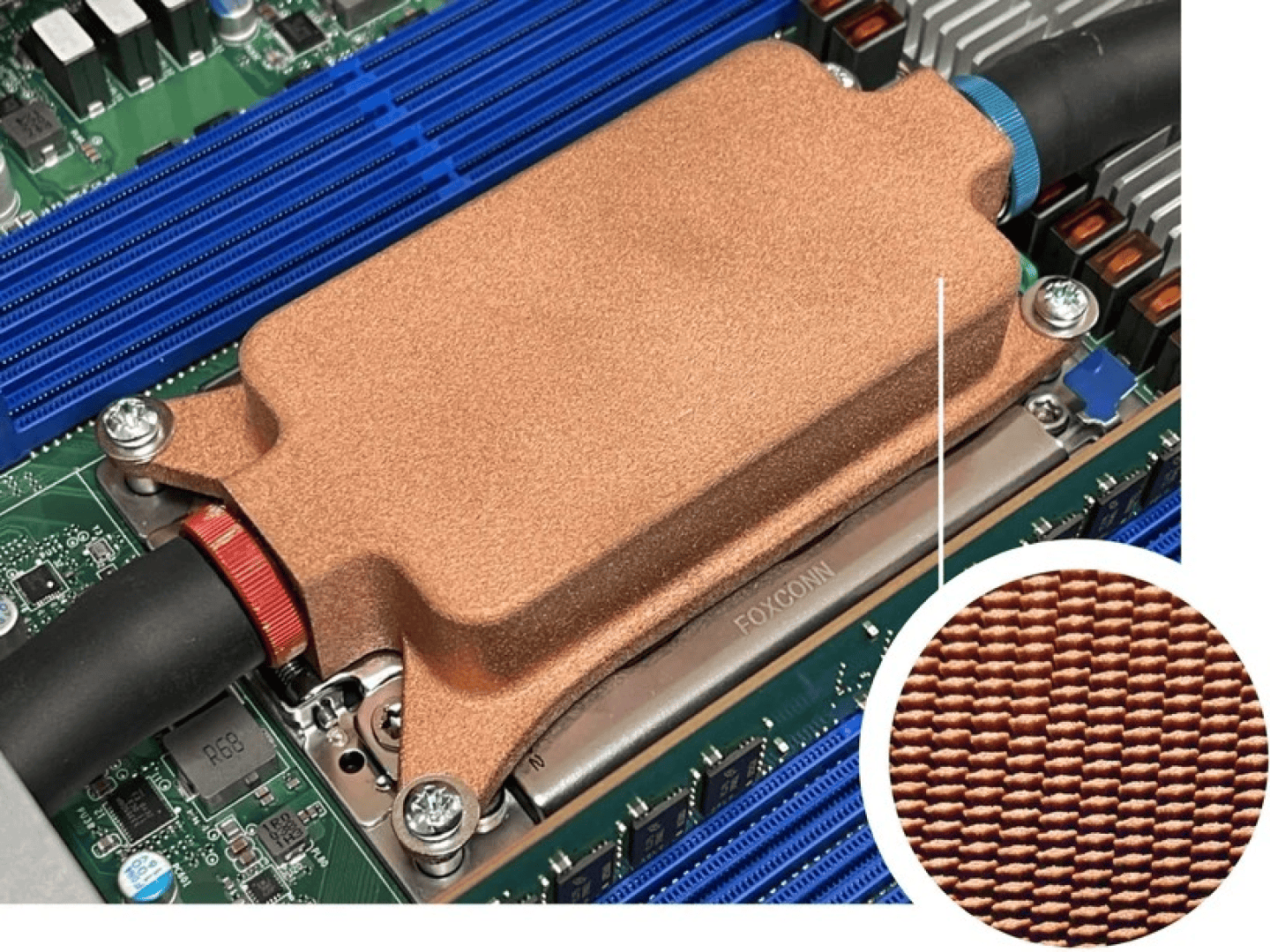

Using the AMCM M 290 1kW system and the validated EOS Copper CuCP process (based on commercially pure copper), CoolestDC developed an integrated, leak-free, liquid-cooled unibody heat sink. This cold plate is built without joints, assemblies, or seals—and withstands water pressures of over 6 bar.

The AM process not only enables highly complex geometries but also allows for the production of ultra-fine internal structures starting at just 0.2 mm wall thickness. The patented angled fins are printed using an optimized process that ensures maximum precision and high-resolution features.

This innovative all-in-one solution eliminates potential leakage risks—which could otherwise cause critical server board failures—while significantly reducing manufacturing complexity by eliminating assembly steps and increasing the component's service life.

Key Benefits at a Glance:

- Leak-free unibody cold plate withstanding water pressure of 6+ bar

- Reduced CAPEX—no tooling costs for different server board layouts

- Design freedom for customized plate thicknesses, fin densities, and positions for optimized thermal performance

Read the full customer success story: Leak-Free Liquid Cooled Heat Sinks | EOS GmbH