Process development for enabling materials

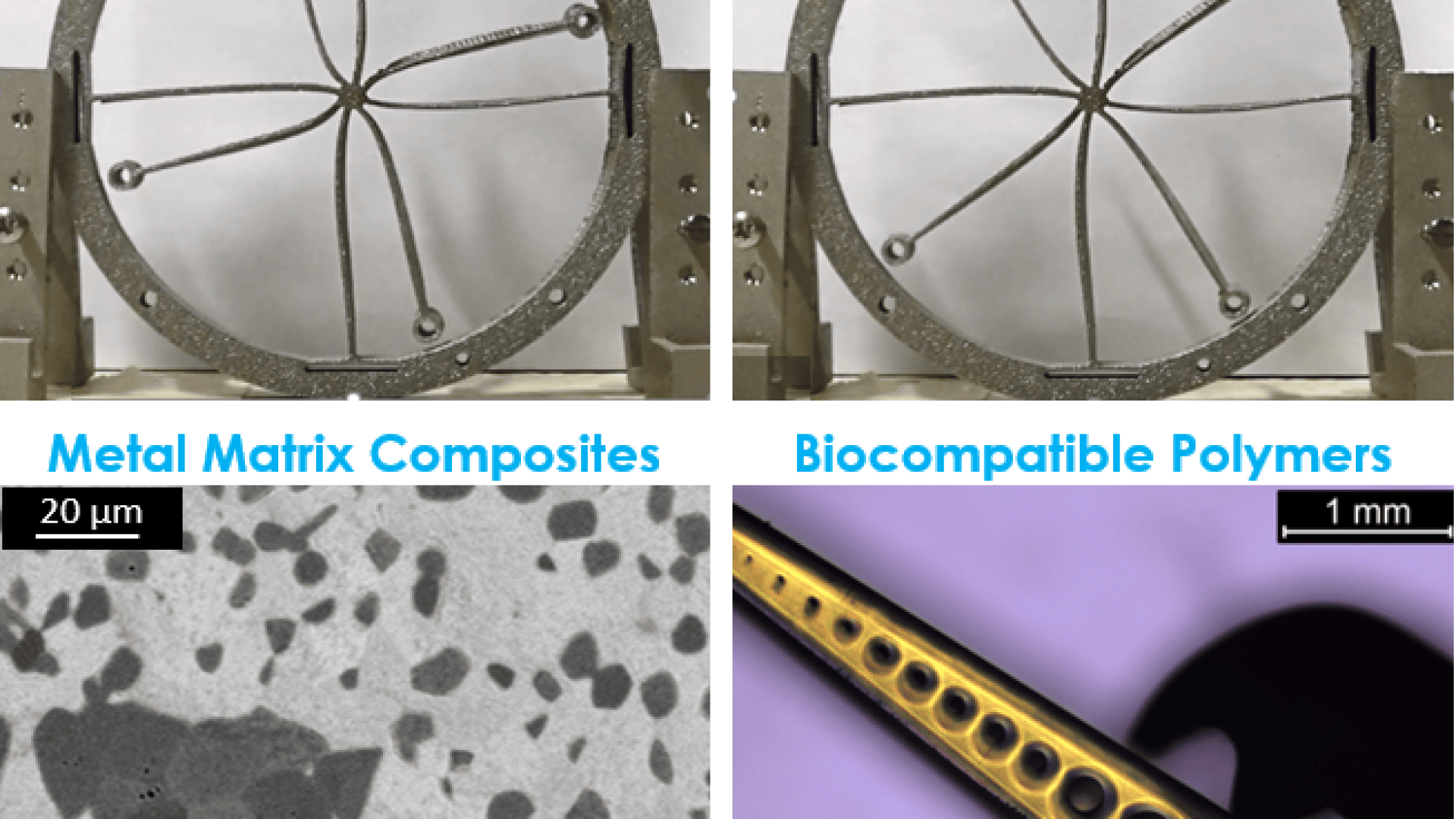

The development of AM process for enabling materials makes it possible to produce parts that could not be manufactured by conventional methods. We currently focus on shape memory alloys, metal matrix composites and biocompatible polymers that provide new functionalities.

The activity demonstrates the major advantages of additive manufacturing in processing advanced materials enabling new applications and functionalities.

Shape Memory Alloys (SMAs) are an interesting class of metallic materials that can recover their initial shape after deformation upon heating above the phase transformation temperature. There has been a growing interest in the additive manufacturing (AM) of SMAs, which are considered promising materials for applications in many industrial sectors. This is true for Nitinol (NiTi), one of the most commercially successful SMAs commonly available only in a limited number of shapes due to difficulties in fabricating parts using conventional methods. In this regard AM promises much needed versatility in design using SMAs, thus developing new potential applications including novel actuators.

Metal Matrix Composites (MMCs) offer the toughness and ductility of a metal with the high stiffness and strength of a brittle reinforcement phase (usually ceramic) that allow to engineer the needed properties for a specific application.

Biocompatible polymers allow to 3D print tools for life sciences with complex designs for fluid handling, biogel molding, and customized parts production based on 3D scans. Using stereolithography, we specialize in high-resolution AM to achieve small tolerances and microfluidics integration.