Schubert Additive Solutions leverages NX to achieve digitalization and cut part lead times by 90 percent

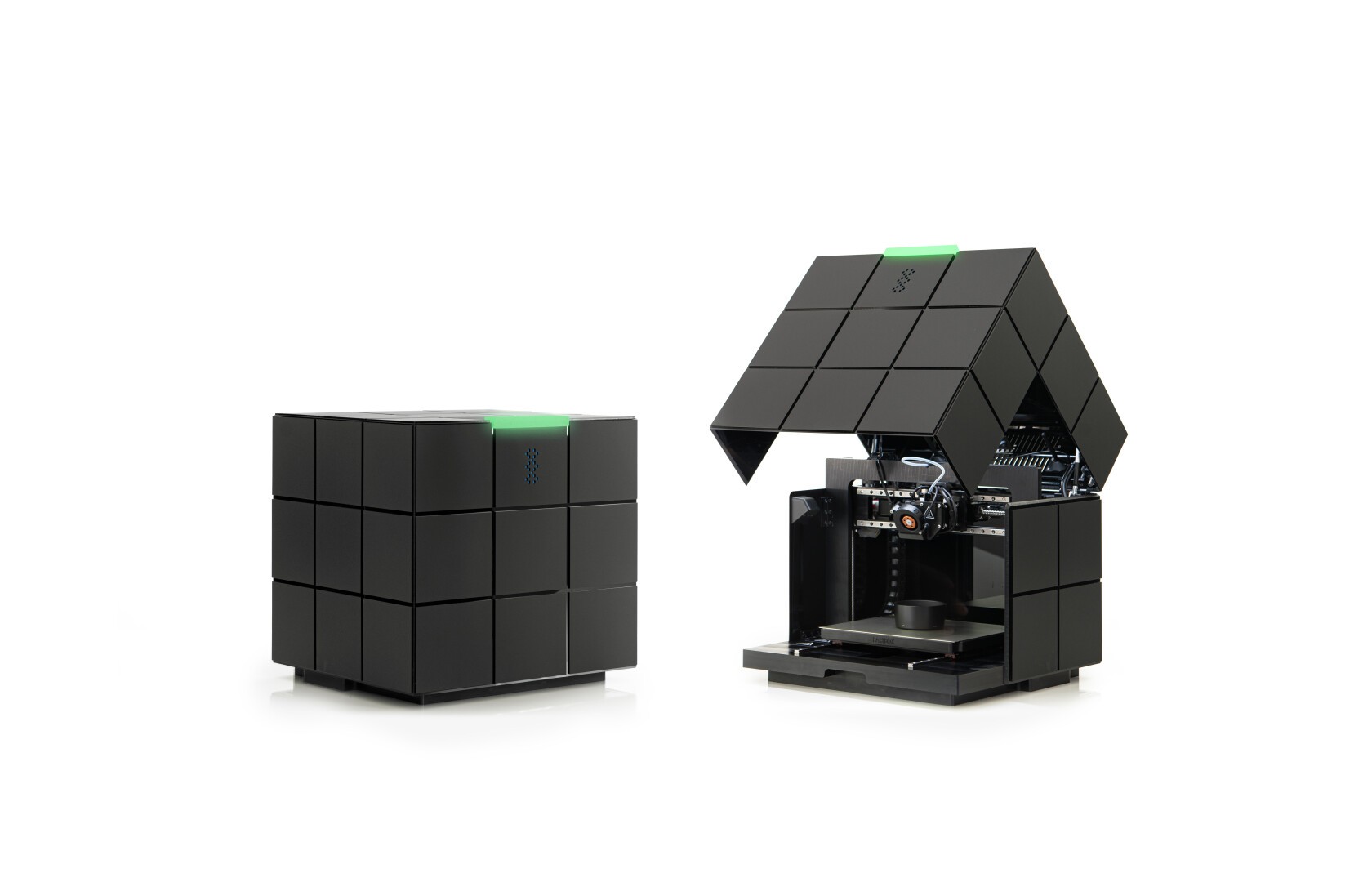

Schubert Additive Solutions provides a solution for decentralized on-demand part production called Partbox. This consists of a part manufacturing data streaming platform, 3D printers and the matching plastic filament enabling customers to buy custom part designs and print the parts locally.

Challenges

- Design industrial-grade 3D printer

- Facilitate fast AM-friendly part redesigns

- Create 3D printer operating system

- Build secure global print job streaming platform

Keys to Success

- Build digital twin of machines

- Use NX for 3D printer design

- Use NX AM functionalities for part redesigns

- Employ the Siemens Additive Manufacturing Network as a global digital parts exchange of data

Results

- Designed industrial-grade 3D printer in a few weeks

- Reduced parts lead time by over 90 percent

- Reduced parts redesign for AM from days to hours

- Built a secure print job streaming platform and 3D printer operating system

Thanks to the end-to-end data consistency across all parts of NX, we were able to weave a digital thread through all aspects of this game-changing process.

Conrad Zanzinger, Chief Technical Officer, Schubert Additive Solutions

Reducing lead time for complex parts

Schubert Additive Solutions (Schubert Additive) is part of the Schubert Group based in Crailsheim, Germany and is a leading manufacturer of packaging machinery and solutions. The group designs and manufactures digital, robot-based packaging machines with a focus on the interplay between simple mechanics, intelligent control technology and scalable modularity. The Schubert Group (Schubert) provides turnkey solutions for primary and secondary packaging for a wide range of industries, including pharmaceuticals, cosmetics, beverages, food and confectionery and technical products.

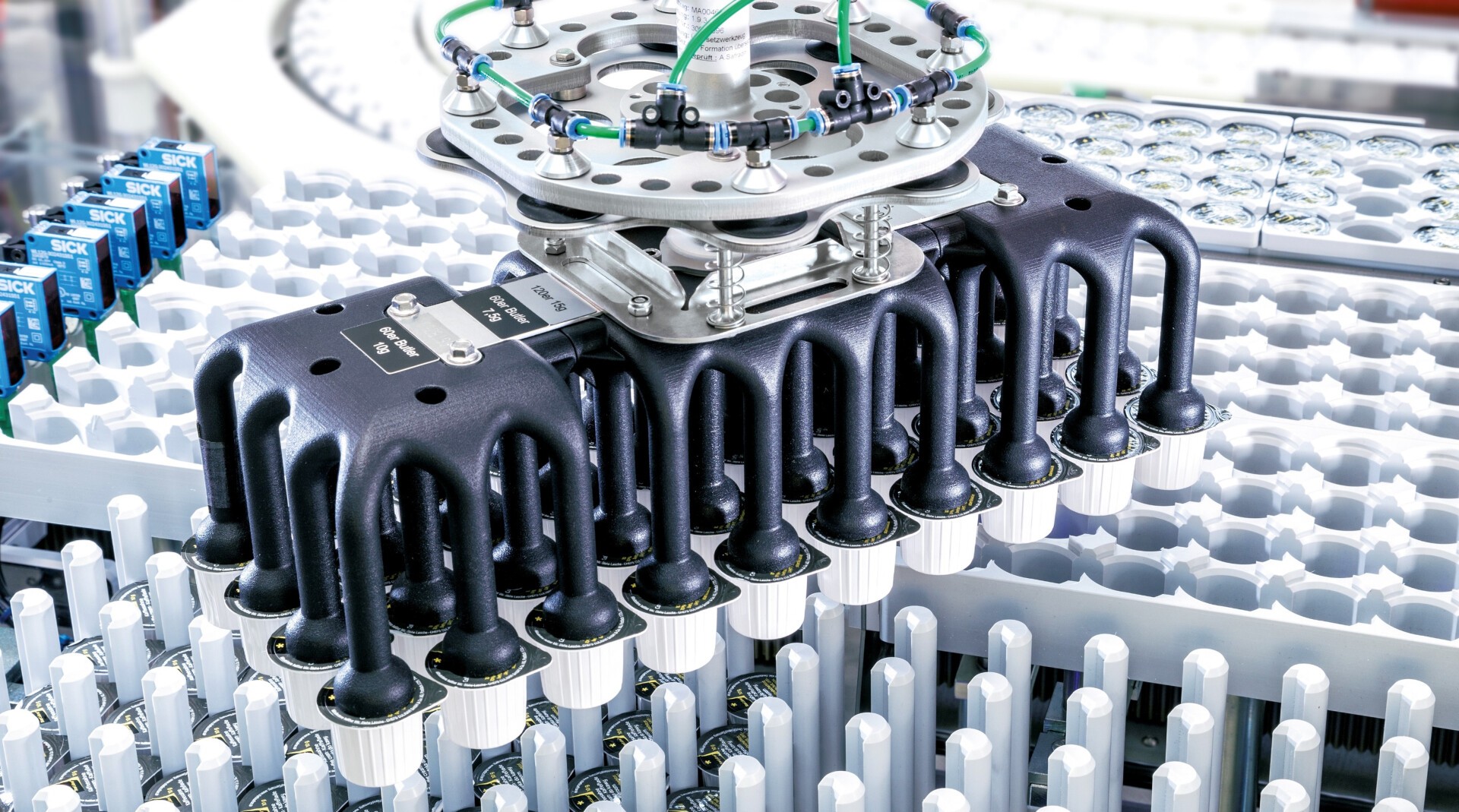

Packaging applications often require complex parts and assemblies in small quantities. Consequently, Schubert was an early adopter of additive manufacturing (AM) technologies. It has been using selective laser sintering (SLS) since 2012 to produce complex parts that can replace assemblies consisting of up to 190 machined parts.

Custom designed robot grippers are an obvious AM application for matching the product to package. “These key components in Schubert’s robot-supported packaging solutions need to be available fast, be it as spare parts or to support product changes,” says Conrad Zanzinger, chief technical officer (CTO) at Schubert Additive. “Even though they were produced on AM equipment, they still took several days to arrive where needed.”

This prompted the idea of leveraging digitalization to significantly reduce lead times for AM components by reversing the supply chain. Schubert Additive found just the solution to help them do this in NX™ software from Siemens Digital Industries Software, a complete design-to-manufacturing solution. It helped the firm transform part supply by designing an industrial-grade 3D printer in a few weeks and cut part lead time by 90 percent.

Designing an industrial-grade 3D printer

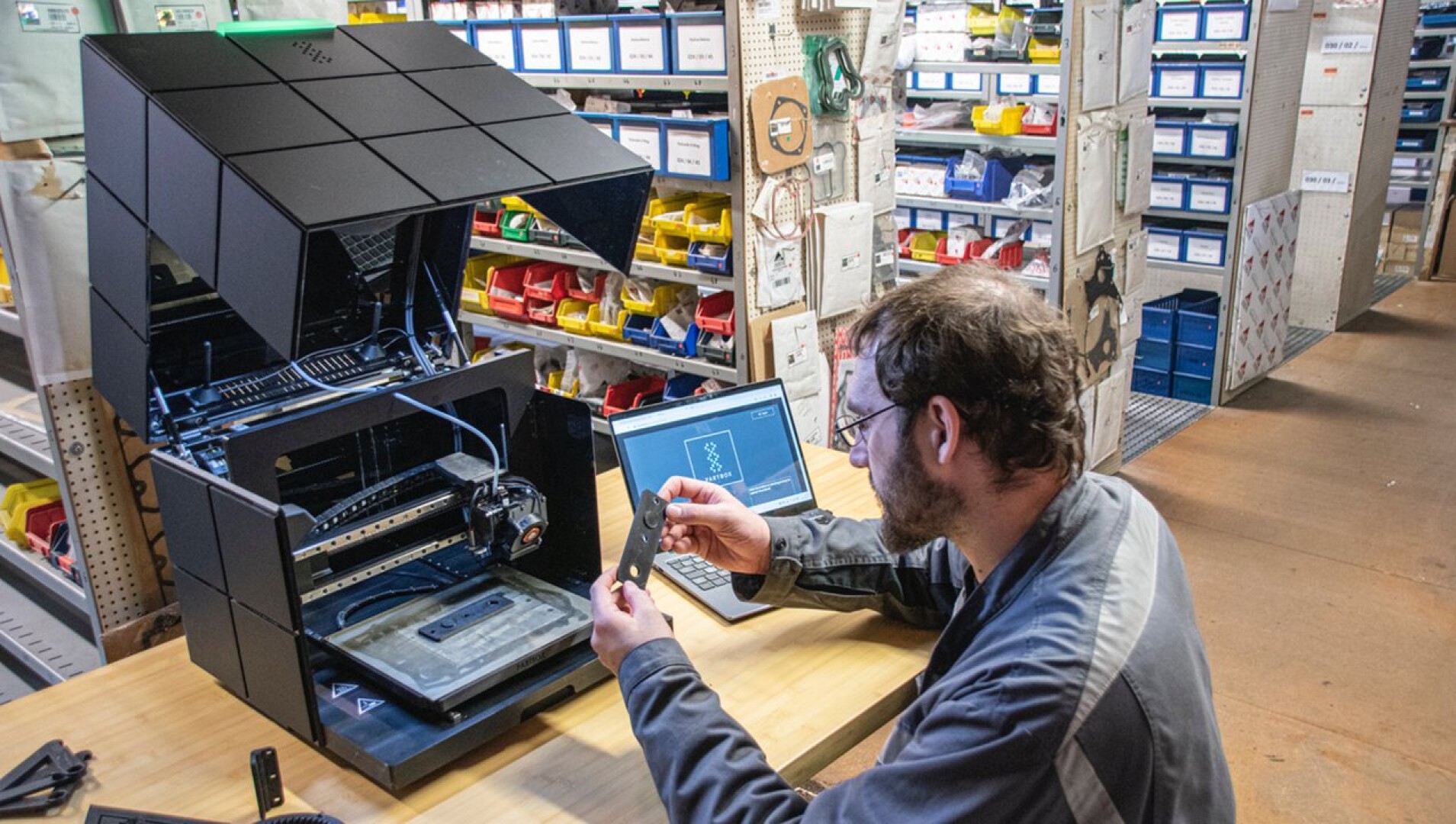

“Most of the required parts can be made of plastic material with 3D print using fused filament fabrication, a proven technology that has been used for years,” Zanzinger notes. “Schubert Additive was founded to enable customers to receive the digital manufacturing data of the ordered parts and produce them on site using industrial-grade additive manufacturing on a pay-per-use basis.”

Before this became feasible, Schubert Additive needed to overcome several obstacles. One was the quality and reliability of the 3D printing equipment. “Initially, we used off-the-shelf 3D printers from a leading manufacturer,” says Zanzinger. “Unfortunately, this equipment did not meet our expectations.” These products lacked in mechanical stability and printing quality. They did not reliably produce parts with the required dimensional accuracy and surface quality and needed an amount of attention that is unacceptable in the context of occasional use in an industrial production environment.

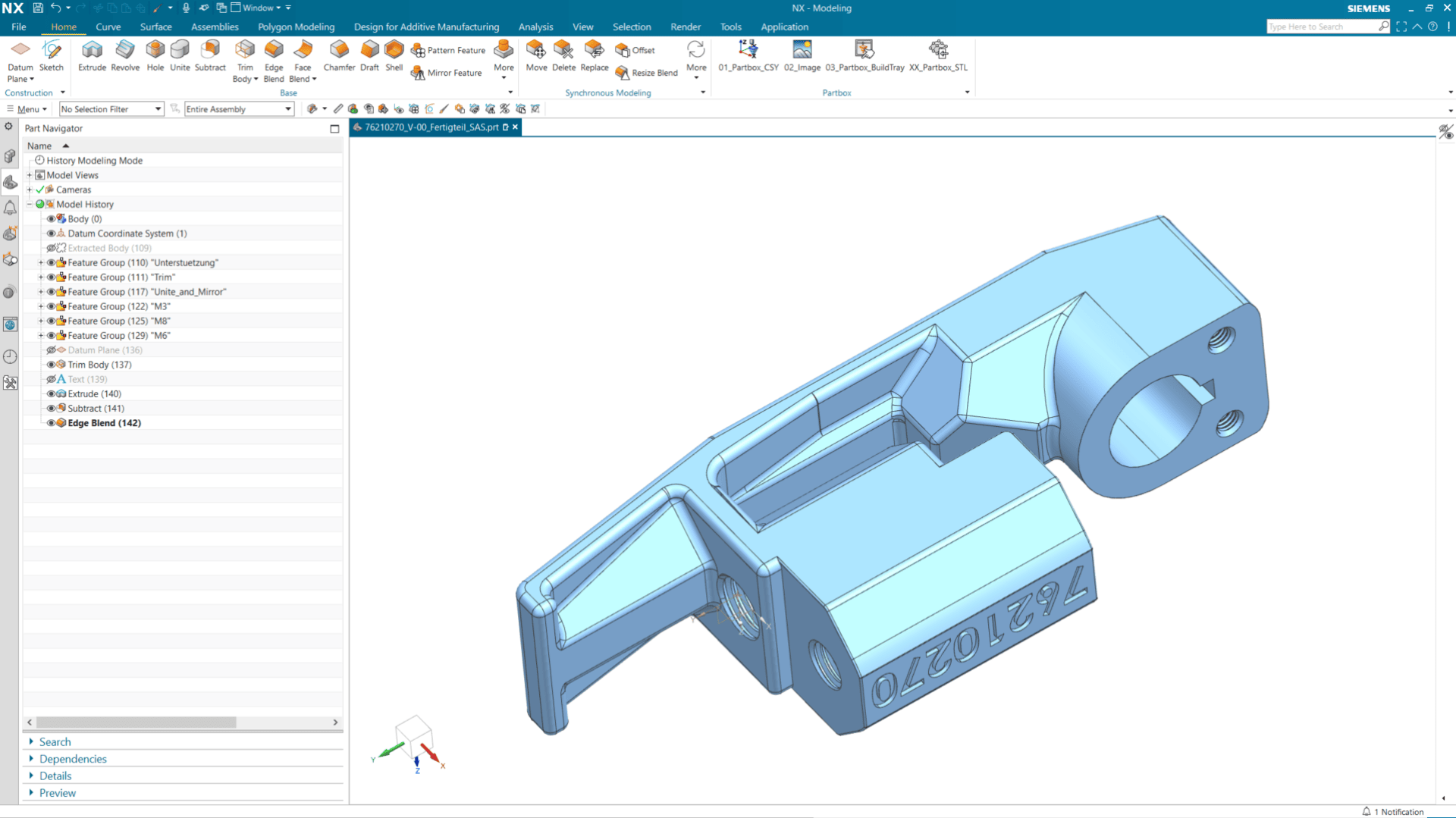

To fulfill these requirements, Schubert Additive used NX, which is part of the Siemens Xcelerator business platform of software, hardware and services, to create an entirely new 3D printer called the Partbox solution. It includes software for computer-aided design (CAD), computer-aided manufacturing (CAM) and numeric control (NC) programming for tooling and fixture design, part quality control, robot programming, production line planning and additive manufacturing. As the Schubert Additive engineers were pressed for time, the NX combination of specialized software tools with full information consistency came in handy. “By using NX to create and verify the digital twin of the Partbox, our design engineers were able to complete their task in a matter of weeks in spite of difficult working conditions during the COVID pandemic,” Zanzinger confirms. “It helped a lot that they were confronted with only one user interface for mechanical design and verification, program generation and the AM-specific tasks.”

To achieve the required stability and reliability, Schubert Additive engineers leveraged the tools for design, topology and build preparation optimization included in NX for AM. This included slicing software, which they had been using previously with their off-the-shelf 3D printer. When they switched to NX it did not require any changes to programming.

A global AM environment

“Using the cutting-edge design tools and specialized AM features available in NX also makes it easy for part providers to remodel conventional designs for additive manufacturing,” states Zanzinger. “This boosts the availability of parts in this form even if they were originally created for conventional manufacturing.” The seamless associativity and reproducibility reduce the necessity to import and export files or even recreating existing designs, considerably cutting the time required as well as conversion errors.

Another obstacle the Schubert Additive team needed to overcome was security, specifically for protecting the intellectual property of the part designers. “Transferring files to the customer was out of the question,” says Zanzinger. “We had to find a secure way to stream certified print jobs straight to Partbox without storing the data where it could unrightfully be retrieved.”

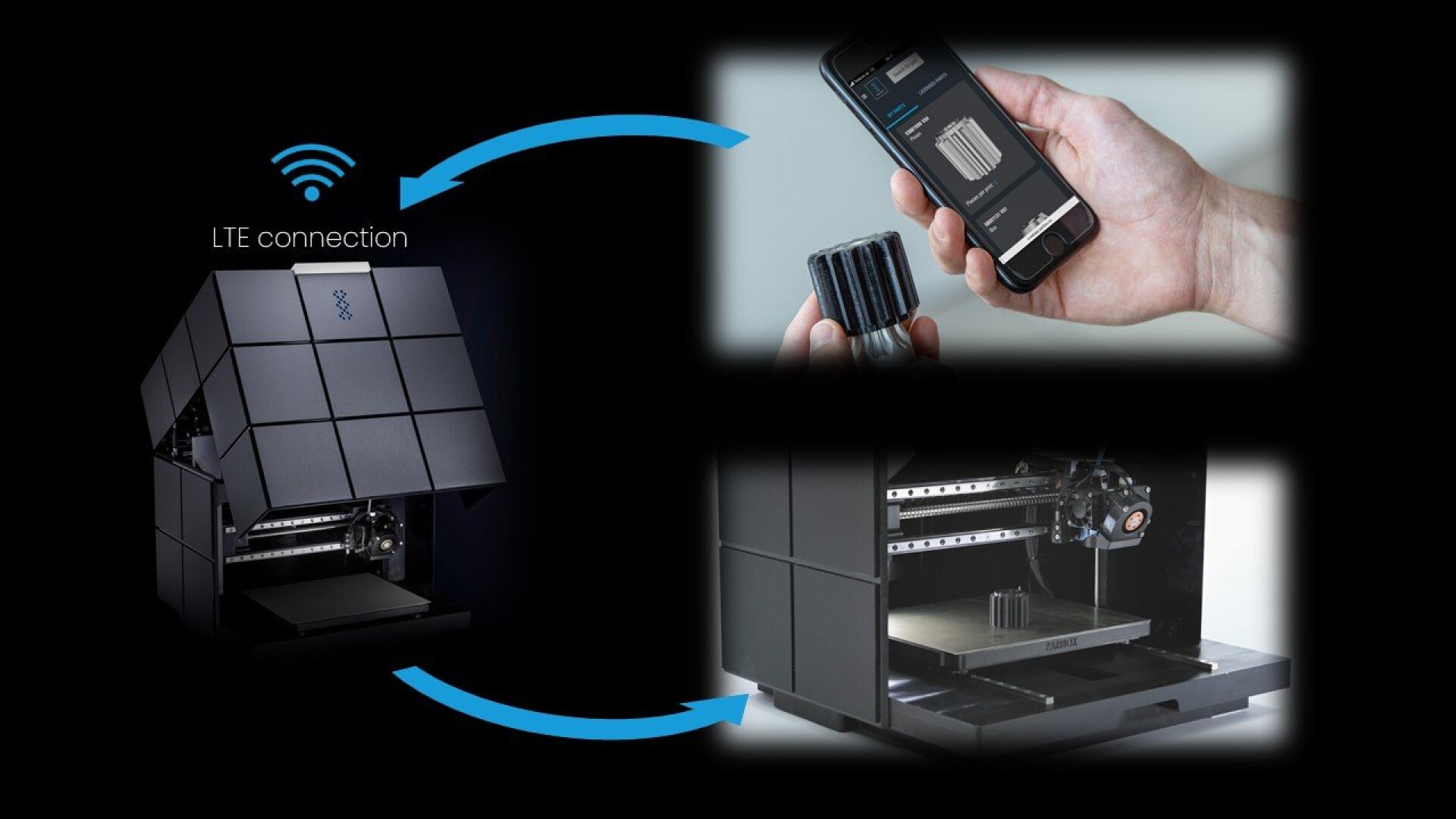

To overcome this obstacle, Schubert Additive engineers created the Partbox operating system, including CAD files for redesign, which are received via Siemens Additive Manufacturing Network. As an online digital warehouse, this operating system allows customers to get printing licenses rather than real parts from part manufacturers. These licenses in the form of Certified printing jobs® (CPJ) are the technical DNA of the system. They are streamed to the selected printer through long-term evolution (LTE) connectivity so Partbox printers do not require networking infrastructure and integration with corporate networks.

The Partbox operating system is open, so customers are not restricted in their choice of vendors. They can also upload their own parts or fixtures print jobs and store them in the part streaming platform to print them when and where needed. They can thus reduce inventory while keeping part availability high. Buying CPJs rather than parts and producing them locally on Partbox 3D printers is more sustainable as it avoids transport-related pollution. It also saves time as it eliminates processes, shipping costs and customs clearance.

Partbox on-demand part production typically takes one day, including an AM-friendly redesign, as opposed to 1.5 weeks, including shipping. This is a reduction of more than 90 percent. In case of spare parts, this can mean the difference between uninterrupted operations and several days of downtime. “We used our digital transformation to revolutionize part distribution and production,” says Zanzinger. “Thanks to the end-to-end data consistency across all parts of NX, we were able to weave a digital thread through all aspects of this game-changing process.”