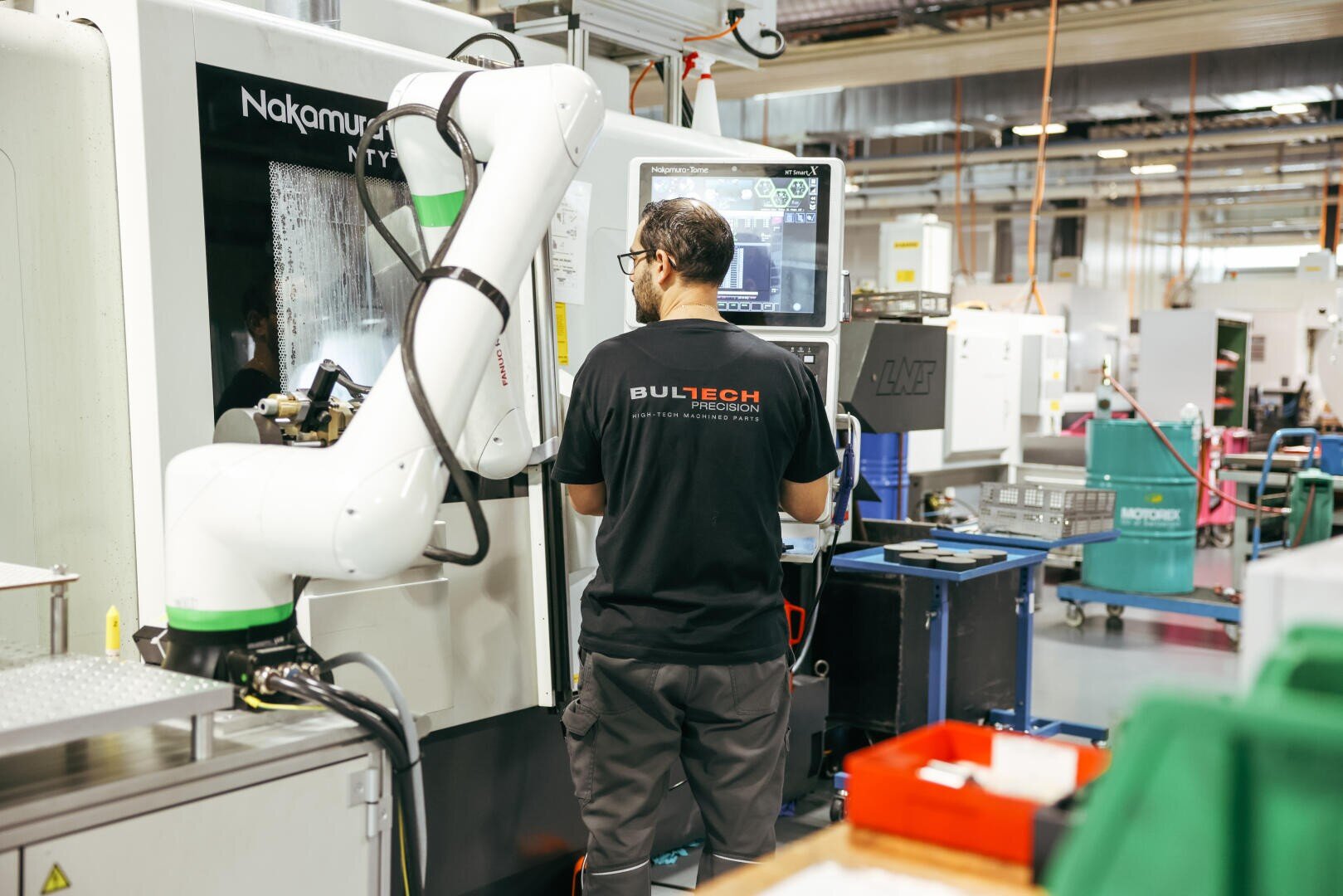

Trademark precision and efficiency

Gruyères is known for cheese and its medieval castle – but few know that nearby in Enney, Bultech Précision SA produces high-precision metal parts for global customers, relying exclusively on MOTOREX high-performance cutting oils for top manufacturing quality.

Bultech Précision SA’s success story can be summed up in the words “high-tech machined parts”. Since it was founded in 1989, the company has developed into a globally valued manufacture of high-precision parts and assemblies. These are manufactured in small, medium and large production runs from materials such as steel, stainless steel, aluminum, titanium and copper alloys. High-performance CNC machines are used to turn, mill and grind the parts. The company’s offering extends to downstream processes such as laser etching, polishing, assembly into complete units and a full logistics service that includes item management and warehousing. Around 20% of its output is exported to customers in all corners of the globe in industries such as power generation, automation and hydraulics, mechanical engineering, medical technology, metrology, clock- and watch making, micromotors and defense technology.

One step ahead of the competition

Supplier companies face huge pressure, competing for every order with low-price bidders in the Far East and eastern Europe. Bultech’s Managing Director, Jean-Marc Egger, sees this as more of a challenge than a threat. “That starts with raw materials and production resources, then continues through engineering, actual precision manufacturing, quality assurance and through to providing a full logistics service. Then it’s easy to get customers who take a total cost perspective on board”. However, this demands state-of-the-art production resources and highly skilled employees with the ability to optimize processes. For this reason, Bultech has 20 CNC lathes, eleven CNC machining centers and four CNC grinders. However, Jean-Marc Egger attaches even greater importance to the knowledge and experience of his employees, who receive continuous training to guarantee the company achieves unique precision and efficiency.

From supplier to development partner

Production of a complex workpiece from nickel provides a showcase example of the Bultech philosophy. Nickel is heat-resistant, tremendously hard even at high temperatures, and is extremely corrosion- resistant as well. However, these properties often push tools and machiners to their limits. Nickel generally tends towards work hardening, which means that the metal surrounding the cutting tool gets much harder to machine as the process progresses. This makes it crucial to choose a cutting tool with the right geometry, hardness, coating and sharpness. Bultech devoted two years to optimizing this process, testing over 300 different tools as it did so. In addition to the tools, different machine outputs, cutting depths, speeds, feeds and cutting oils were tried.

Using DECMED HP-X 22 we were able to raise production capacity and increase tool lives by 50%", sais Jean-Marc Egger, Managing Director at Bultech Précision SA

Cutting oil—a productivity factor

Bultech has been working with MOTOREX for years because it believes MOTOREX lubricants are the best on the market. However, Bultech has been won over not only by the quality of MOTOREX products, but also by the expert advice and development partnership offered by the lubricant specialist. Since cutting oil has a significant impact on overall productivity, a wide variety of products from MOTOREX’s extensive range were tested with the process. The best solution was 22-viscosity DECOMED HP-X from the SWISSCUT DECOLINE. Using this cutting oil tripled cutting speed and increased tool life by 50 percent. Bultech was also able to produce significantly more parts than with conventional solutions in the same time. MOTOREX’s high-end cutting oil for perfect surfaces and dimensional accuracy also offers a large number of additional benefits. It contains no chlorine, zinc or other undesirable components, which ensures excellent compatibility with people, materials and machines. The oil’s high flash point, attributable to its Group III+ and GTL base oil, reduces evaporation loss by up to 60 percent, thus also reducing oil consumption. This is further helped by the DECOLINE cutting oils’ very good flow characteristics, which ensure much less oil is lost to swarf and workpieces and in turn reduce not only consumption, but also cleaning work. This MOTOREX cutting oil is particularly suitable for medical technology, because it is not cytotoxic (does not damage cells) under ISO 10993-5 standards.

Environmental commitment

Manufacturers in the Gruyère region care strongly about the environment. Bultech is no exception, attaching huge importance to sustainable production. A roof-mounted solar array generates electricity for the company and waste heat is used to heat the production area. MOTOREX’s SWISSCUT DECOLINE offers a high-performance, odor-neutral and contemporary solution for the cutting oil market. It runs off parts smoothly and is easy to clean. Bultech’s carefully thoughtout fluid management system also recovers oil by centrifugation and filtration, which increases its service life and reduces consumption of fresh oil.

Longstanding, cooperation-based partnership

“MOTOREX doesn’t just sell us a product. It sells us a complete solution that is perfectly adapted to our applications”, says Jean-Marc Egger. As a customer, he also appreciates the personal advice and service package, ranging from laboratory analysis and informative data sheets to the very straightforward ordering process in the online shop. The perfect interplay of the two top Swiss companies is the best example of how to successfully compete with lowwage countries.

Bultech Précision SA

Founded in 1989 and headquartered in Enney, Switzerland, Bultech Précision produces individual parts and assemblies from steel, aluminum and titanium in production runs of various sizes. With its highly innovative production workshop and latest-generation CNC machines, Bultech delivers outstanding quality, competitive prices and high reliability. The company has ISO 9001 certification and exports worldwide.

More about MOTOREX INDUSTRIAL LINE.