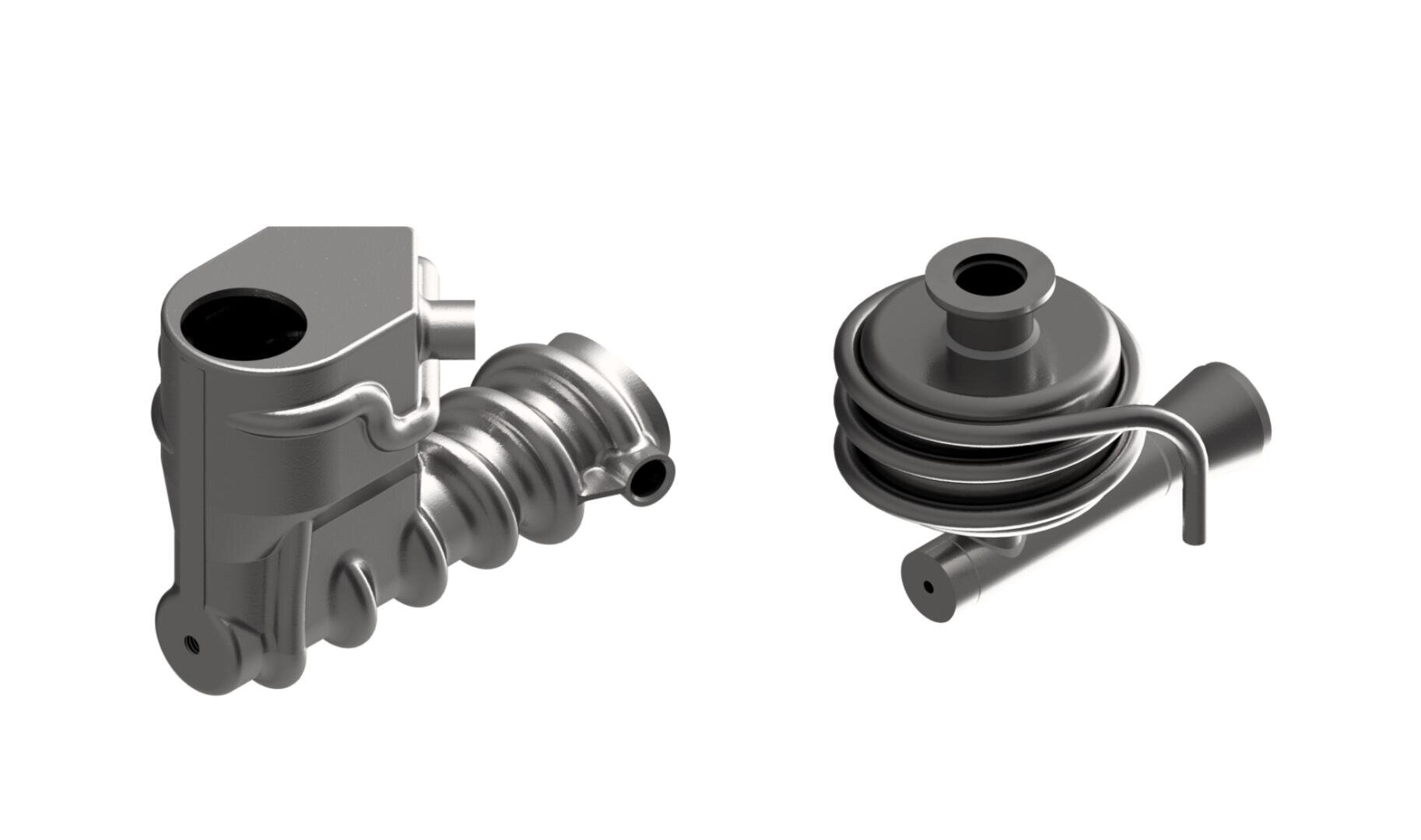

Pre-vacuum baffle – why make things complicated when they can be simple?

A complex subassembly was replaced by a single 3D-printed component during a redesign. The presentation should not focus too much on the function, but rather highlight the approach to the problem and serve as inspiration for your own company.

HSR AG, based in Balzers, was faced with a task that many of us are familiar with. The penultimate batch of stock items for a product had been ordered and delivered, and it was high time to place another order. Fortunately, in this case, it caused some headaches: the assembly consisted of so many individual parts that had to be screwed, welded, and soldered together at enormous expense. To keep the price reasonably acceptable, a minimum quantity would have been unavoidable. In addition, only someone with a great deal of experience could solder the tubes, and the old soldering gauges would also have had to be replaced.

There had to be an easier way!

And there was. In this presentation, you will learn how the customer arrived at an optimized solution step by step, starting with the task at hand. And finally, you will learn what impressive progress can be achieved when previous designs are rethought from the ground up.

Please note: This presentation will be given in German.

Speakers (1)