Reach your goal in a few hours instead of several days

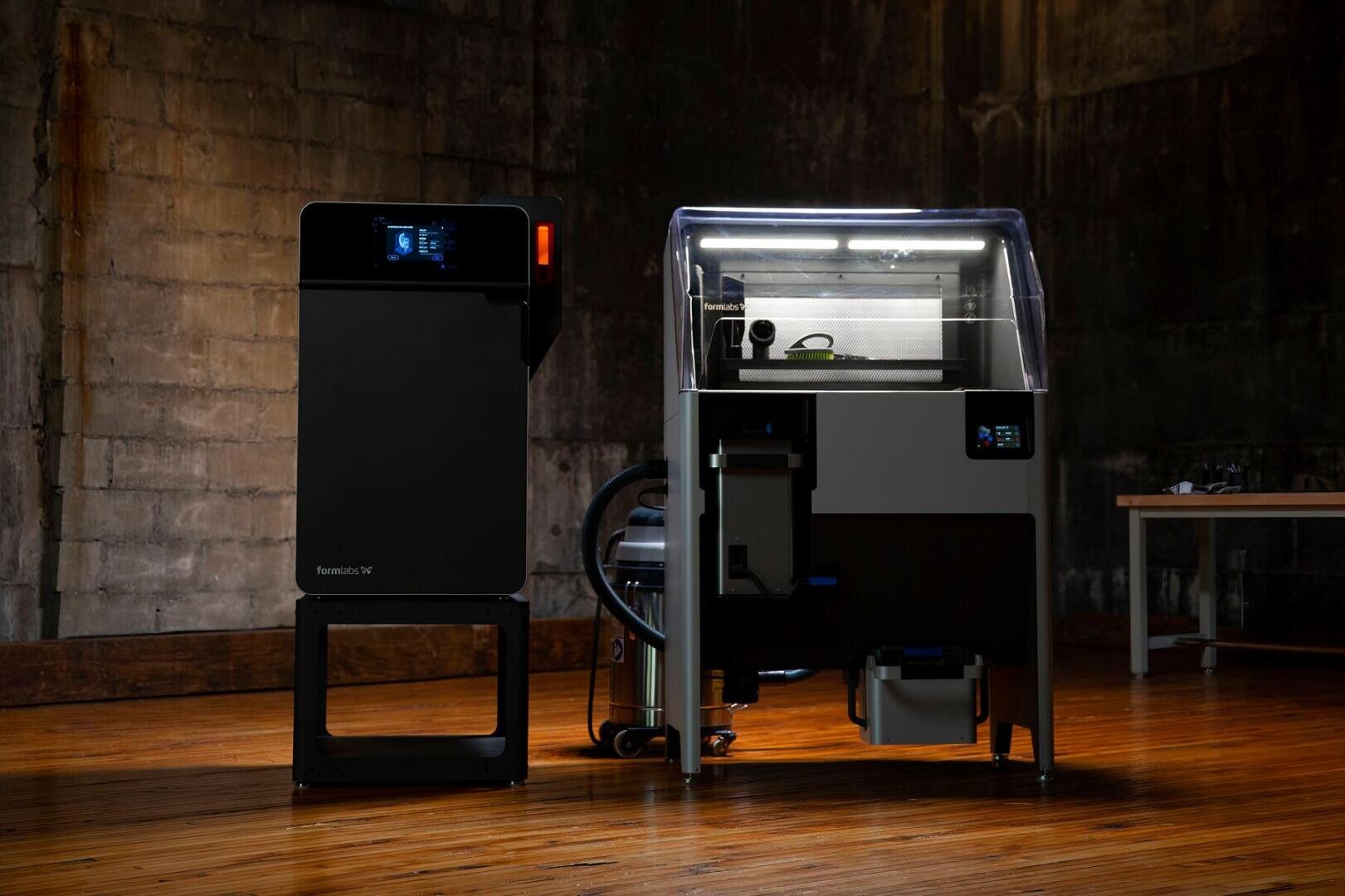

With the Fuse 1+ 30 W from Formlabs, faster and more precise SLS 3D printing becomes a breeze. In combination with the Fuse Sift powder recovery station, waste is massively reduced and unit costs are lowered.

With the Fuse 1+ 30W, manufacturer Formlabs has launched a compact SLS 3D printer that enables maximum output with minimal waste. Thanks to high printing speeds, an expanded range of materials, optimised packing density and improved feed rate, production-ready, industrial-grade 3D printing is now easy to implement in your business. With the Fuse 1+ 30W and the Sift 1 – the post-processing and powder preparation station – Formlabs offers an affordable, compact SLS (selective laser sintering) platform.

High printing speeds

With the Fuse 1+ 30W, you can produce precise parts within 24 hours. This is achieved, among other things, with a powerful 30-watt laser that prints at a scanning speed of up to 12.5 metres per second. By optimising the packing density and refresh rate of the powder, the Fuse 1+ 30W also enables waste-free printing, which massively reduces unit costs. Benefit from a new range of industrial-grade materials and achieve higher performance with existing materials through active powder handling and an inert gas pressure option.

Maximum printing success with easy setup

The Fuse 1+ 30W is set up for printing using the free Formlabs PreForm software. There you import your STL or OBJ files, align the models and arrange them. Printing times are then determined and the data for 3D printing is sent to the machine. With just a few clicks of the mouse, numerous models can also be automatically arranged in the build space. PreForm's algorithms for arranging parts automatically align the models. This increases the packing density, which shortens the printing time and reduces waste.

Manage print jobs from anywhere

The intuitive touchscreen user interface guides you step by step through the machine setup and print preparation. A live stream of the print bed is displayed during printing. This allows you to watch your parts take shape layer by layer. This camera view is also displayed on the computer in PreForm, allowing you to monitor printing from your desk. With the cloud-based dashboard, you can maintain control over your production even with multiple locations and machines. Track print jobs and material levels to ensure minimal downtime and maximum throughput.

How does SLS 3D printing work?

In the SLS 3D printing process (selective laser sintering), polyamide powder (nylon) is fused together layer by layer. The unfused powder within the build chamber supports the parts during the printing process. This allows complex, movable or connected components to be manufactured without support structures. The Fuse 1+ 30W uses SLS technology (Surface Armour Technology) developed by Formlabs, in which a semi-sintered shell is printed around the surface of the part. This technology is patented. This enables Formlabs to offer competitive mechanical properties and high surface quality in an affordable SLS 3D printing system with the Fuse 1+ 30W. The quality of the components can be increased with the Fuse 1+ 30W through optional printing in an inert gas atmosphere. This allows you to achieve industrial quality in the smallest of spaces and without industrial requirements.

Clean powder recycling

Several parts of the pre- and post-processing stages of SLS 3D printing are combined in the Formlabs Fuse Sift powder recovery station. This device is used for part removal, powder recovery, storage and powder preparation. With the Formlabs Fuse 1+ 30W, you can produce fully functional parts, while the high recyclability of the powder – with unlimited cycles – reduces waste and lowers unit costs. The Fuse Sift automatically dispenses used and fresh powder in the correct mixing ratio.

Designed for 24/7 throughput

With the Fuse 1+ 30W, you benefit from very high printing speeds. As a result, you can produce prototypes or small series of end-use parts in less than 24 hours. Achieve virtually uninterrupted throughput by adding an optional second build chamber to the system. This is removable and compatible with the Fuse 1+ 30W, Fuse 1 and Fuse Sift. The build chamber can be removed from the printer just one to two hours after printing is complete. You can then start the next print with a second build chamber. This allows you to achieve uninterrupted throughput on a single machine.