CO₂ - snow blasting and CO₂ - ice blasting in med tech applications

In the field of medical technology, new technologies are constantly being researched to find innovative solutions for various applications. Two promising approaches are the use of CO₂ snow blasting and CO₂ ice blasting.

These advanced techniques offer interesting possibilities, but also have their own advantages and disadvantages. In this article, we take a closer look at these two processes and explain their importance for the med tech industry.

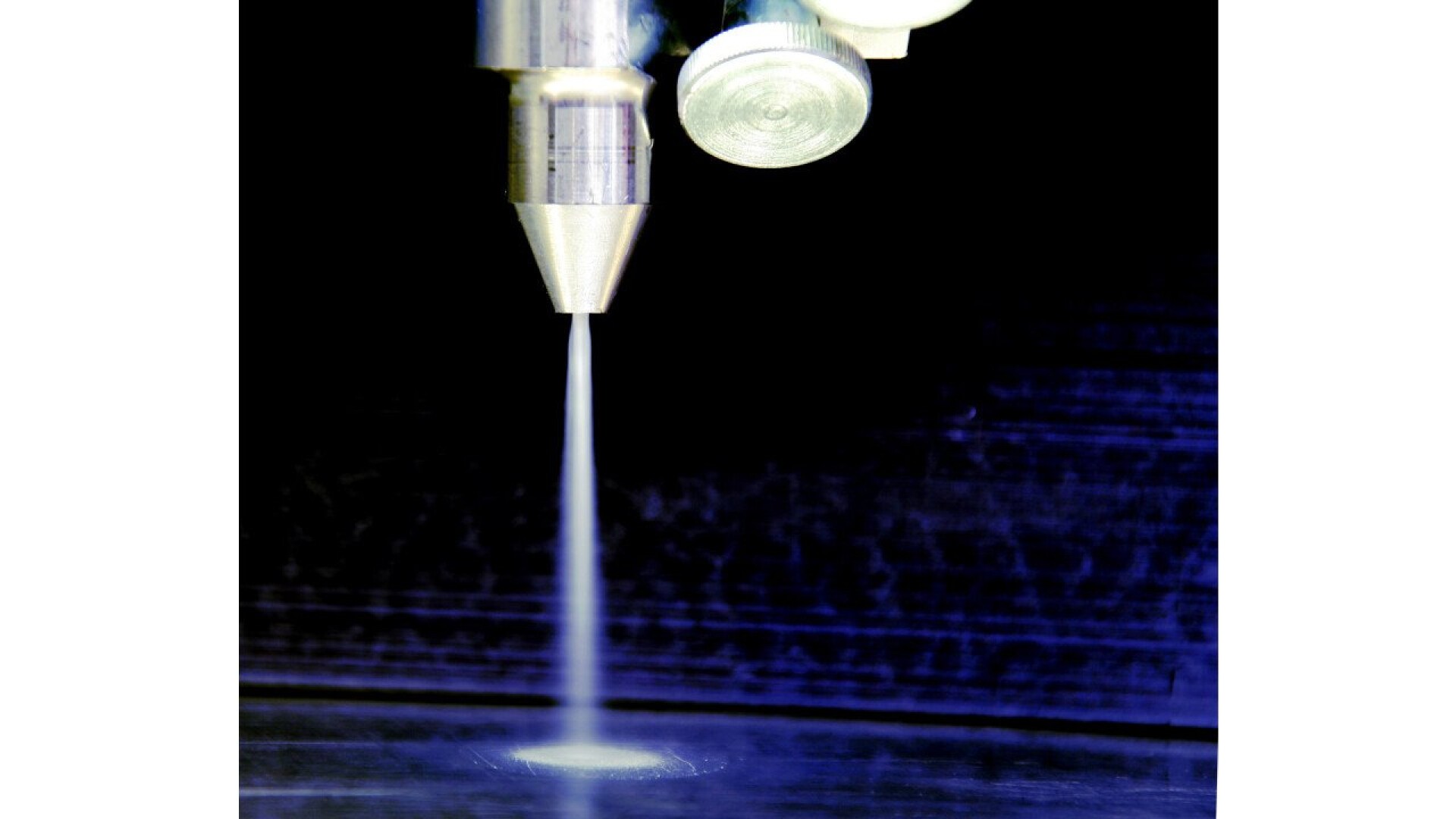

CO₂ snow blasting is a process in which liquid CO₂ is released from the bottle under pressure and converted into a snow jet. This jet is then used for surface cleaning. One advantage of this method is its environmental friendliness, as CO₂ is a non-toxic, non-flammable gas. The process does not produce any residues or waste products, which simplifies the cleaning process. In addition, CO₂ snow blasting can minimize thermal damage to sensitive medical equipment due to its low temperature.

However, there are also potential disadvantages to using CO₂-snow blasting. Due to the high-pressure and low temperature, there is a risk of cold burns or injury if used improperly. In addition, the equipment for generating CO₂ snow jets requires some investment, which may increase the initial cost. Furthermore, not all materials are suitable for cleaning with CO₂ snow jets, which may limit the possible applications.

CO₂ ice blasting uses frozen CO₂ in the form of dry ice, which hits the substrate surface in a jet. The CO₂ ice is usually procured externally, or generated in-house using a dry ice pelletizer. This process offers similar advantages to CO₂ snow blasting, as it also produces no residue or waste products. The ice crystals are slightly more abrasive than the snowflakes, making the technology good for more stubborn, adherent contaminants. CO₂ ice blasting can be used to clean medical instruments, implants or prostheses. It can also be used to prepare surfaces for coatings or to remove deposits.

One of the great strengths of CO₂ ice blasting is that it leaves no moisture behind. This is particularly important for ensuring the sterility of medical equipment. The targeted application of the blast can also clean hard-to-reach areas. However, dry ice can be difficult to handle due to low temperatures, and protective precautions are required to avoid injury.

With both technologies, CO₂ emissions and maximum workplace concentrations must be monitored. Typically, an exhaust system is required in the cleaning room to extract both contaminants and the carbon dioxide, which is now gaseous again. The electrostatics that occur during CO₂ blasting must also be considered in individual cases by using electrostatic discharging devices.

CO₂ snow blasting and CO₂ ice blasting offer interesting applications not only in the cleaning and preparation of surfaces, but also in various areas of medical technology, especially in connection with industrial medical equipment, implants, 3D-printed products, optics and electronics. Here are some examples:

- Cleaning of industrial medical equipment: CO₂ snow jets and CO₂ ice jets can be used to effectively clean medical equipment such as ultrasound heads, endoscopes, X-ray machines and laser systems. These processes enable thorough cleaning, even in hard-to-reach places, which can extend the life of devices and improve the accuracy of their functionality.

- Surface preparation of implants: Careful surface preparation is critical in the manufacture of implants. CO₂ snow blasting and CO₂ ice blasting can be used to remove unwanted contaminants and prepare the implant surface for optimal adhesion of coatings or improved integration with surrounding tissue.

- Cleaning of 3D-printed products: In additive manufacturing of medical components and prototypes, cleaning of printed parts is often a challenge. CO₂ snow blasting and CO₂ ice blasting offer a gentle cleaning method to remove residues such as powder particles or support structures without damaging the delicate 3D-printed structures.

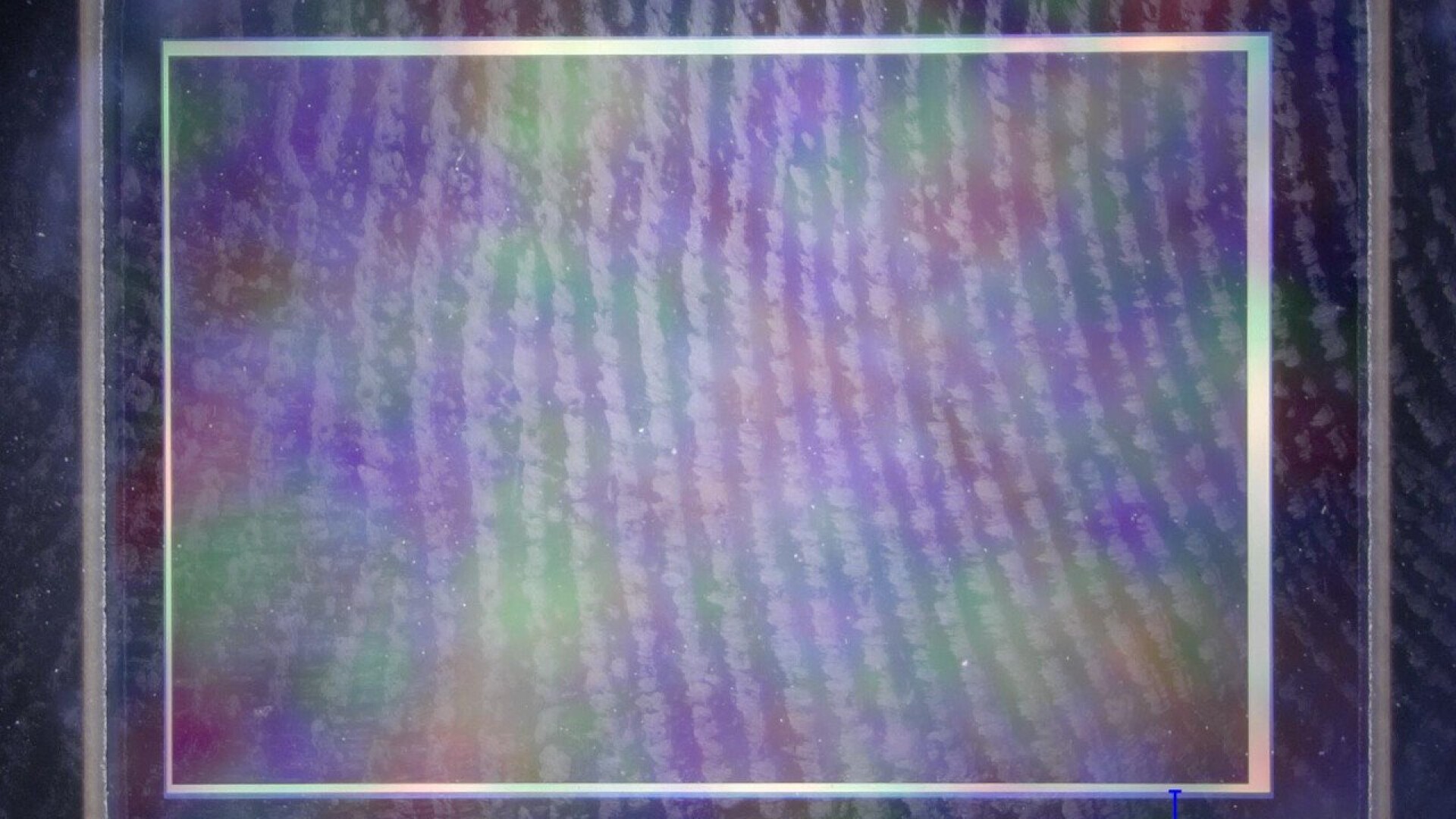

- Cleaning of optical components: Optical systems play an important role in medical technology, e.g. in lasers, endoscopes or imaging procedures. CO₂ snow jets and CO₂ ice jets can be used to clean optical components such as lenses, mirrors or prisms to ensure clear vision and optimum performance.

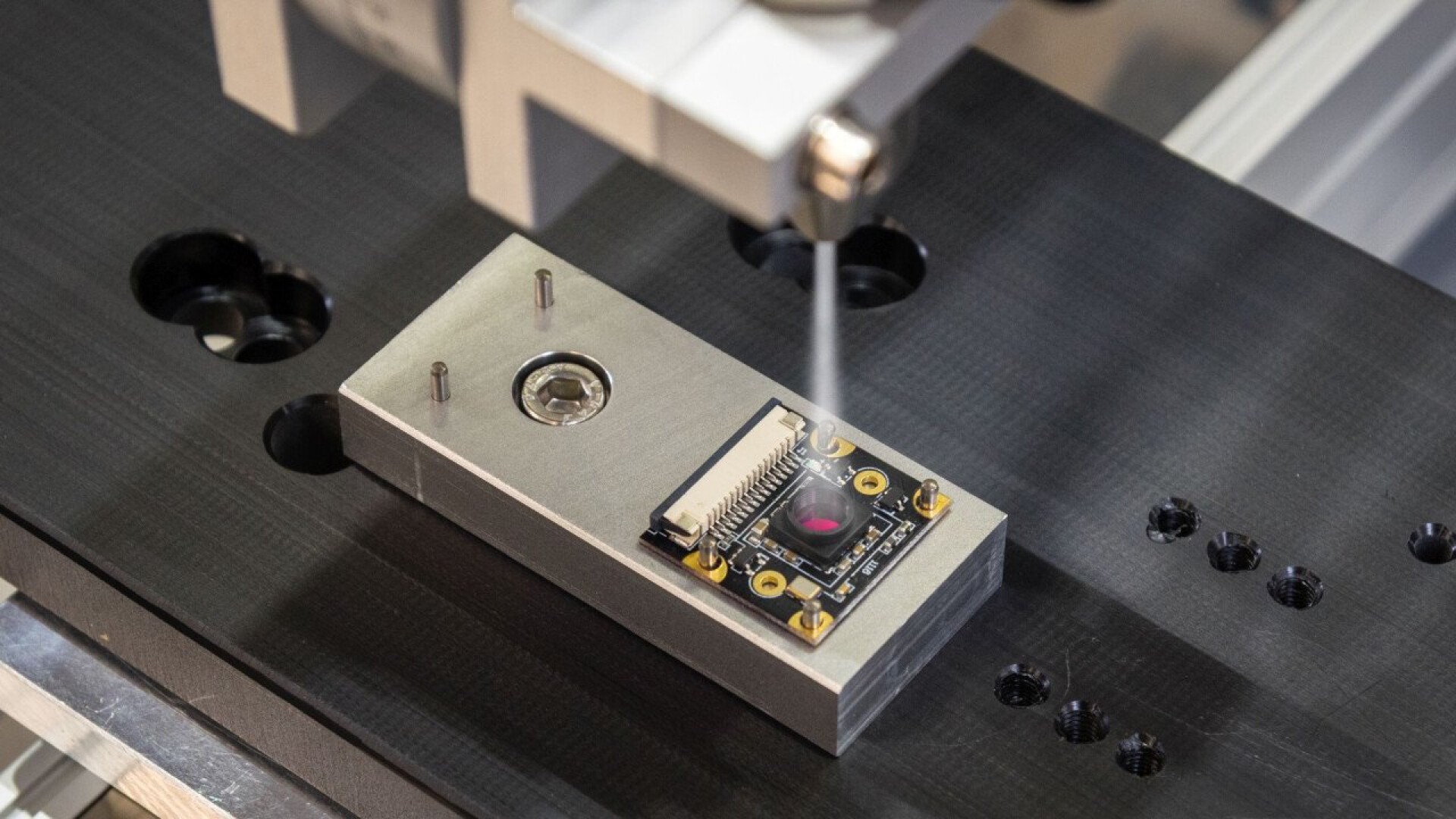

- Removal of contaminants in electronics: In medical technology, electronic components are used in devices such as medical monitors, implant controllers or medical imaging equipment. CO₂ snow blasting and CO₂ ice blasting can be used to clean circuit boards, contacts or other electronic components to remove dust, particles or other contaminants and ensure the reliability and functionality of the electronics.

These applications show that CO₂ snow blasting and CO₂ ice blasting offer versatile solutions to improve the quality, performance and lifetime of equipment. With their gentle cleaning action and precision, these processes help optimize manufacturing processes.

Visit our trade show presentation to learn more about the possibilities and benefits of CO₂ snow blasting and CO₂ ice blasting. Our experts will be available to answer your questions and provide detailed insights into this innovative cleaning technology. Be there and discover the future of surface cleaning!