Design of an additively manufactured hydraulic directional spool valve

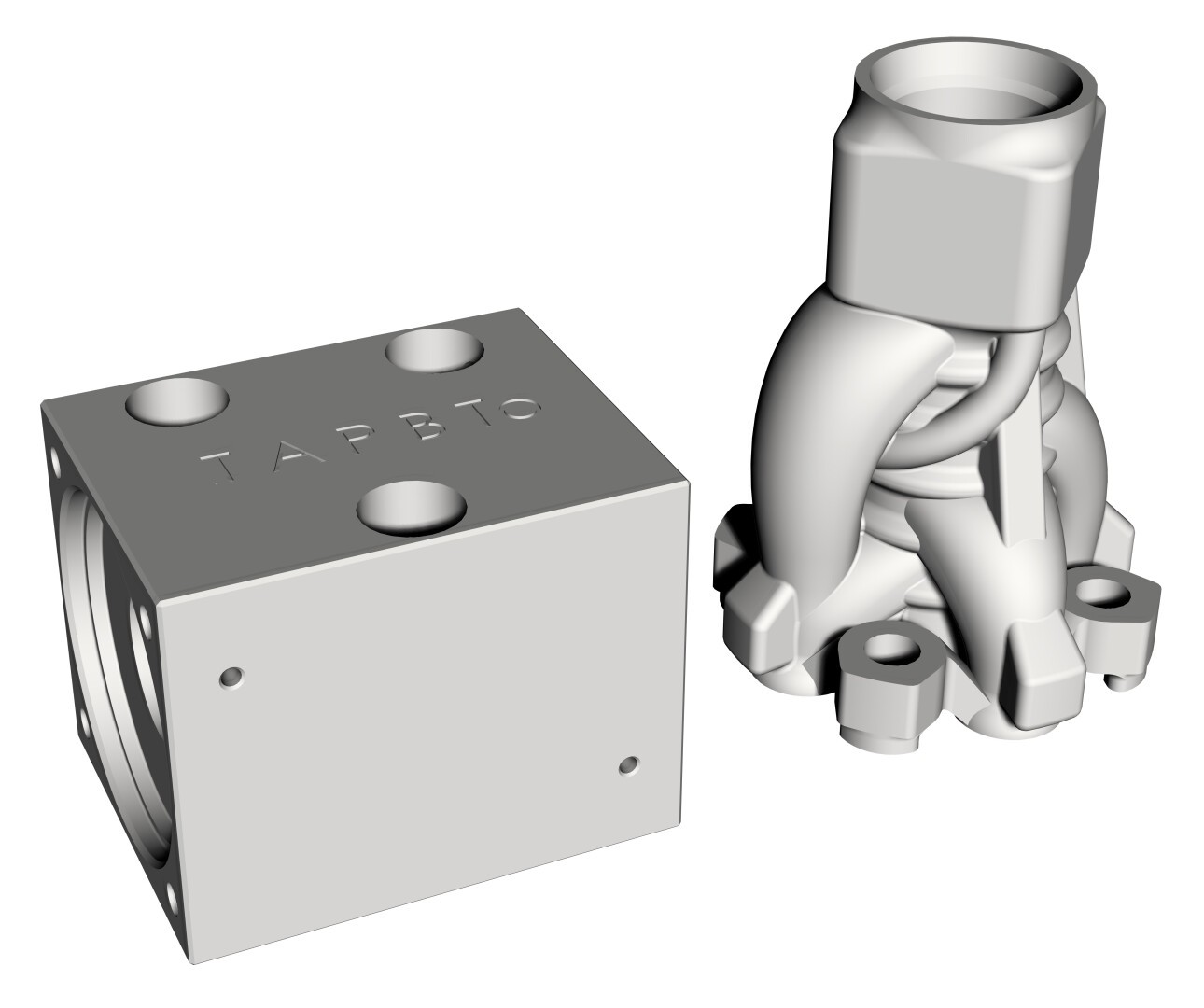

In close collaboration with Wandfluh AG and inspire AG, we developed two sizes of an additively manufactured hydraulic spool valve which exploit the design freedom of the laser powder bed fusion (LPBF) process. Compared to the conventionally manufactured valve, the pressure drop was reduced by 60%.

Hydraulic systems have been used for decades in many industries and remain a commonly used power source for actuation in various systems and applications. In most cases, hydraulic components are conventionally produced by milling and drilling channels into metal blocks, making them bulky and significantly limiting the design options for these components. Only the channel diameter and position can be varied, leading to sharp 90° bends and dead ends at the intersections of channels. This leads to a significant pressure drop and consequent energy loss.

However, in certain applications an increased efficiency and reduced weight of the hydraulic components are essential; for example the use of remotely operated vehicles (ROVs) for underwater applications, which are used for inspecting and repairing of subsea pipelines.

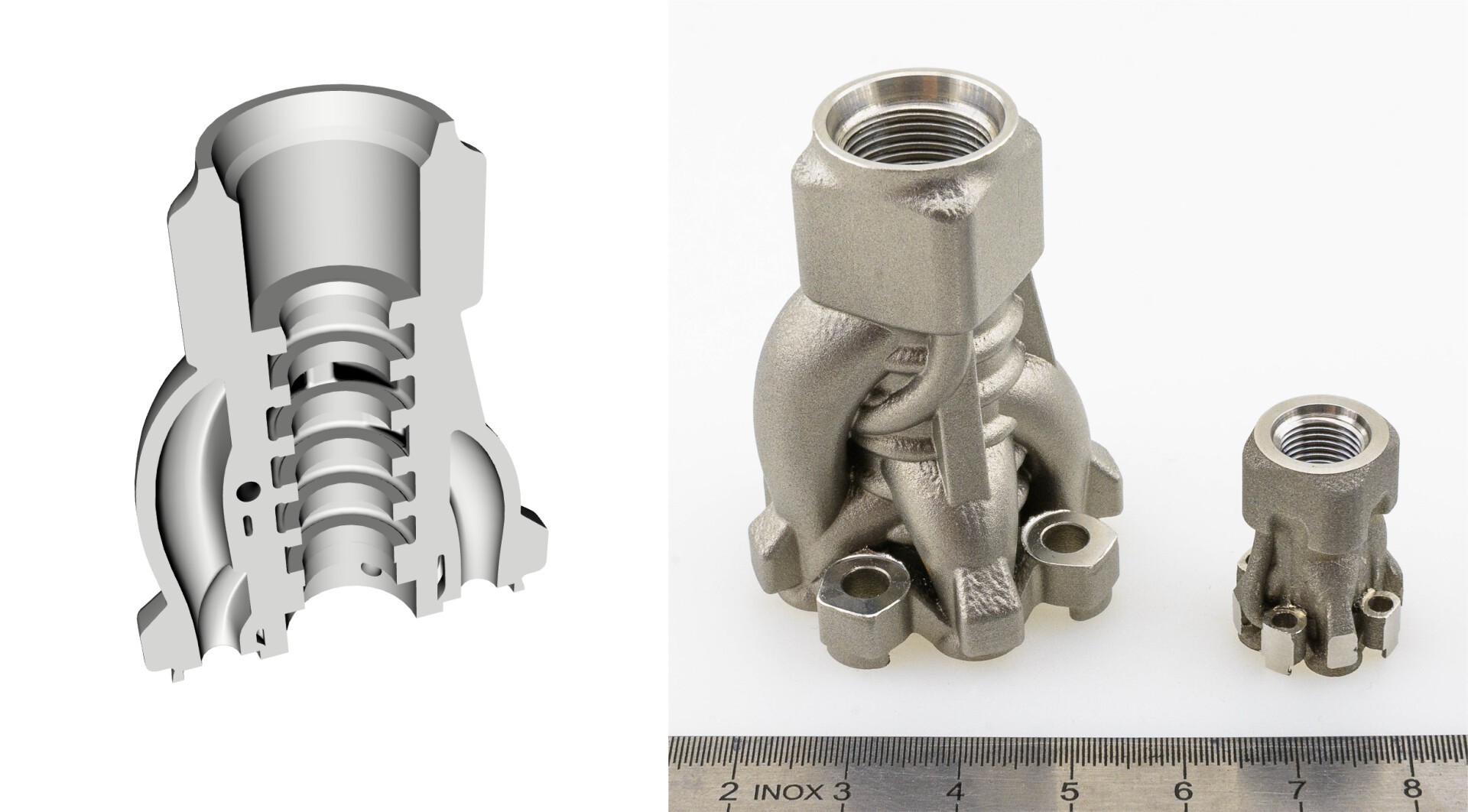

In contrast to conventional manufacturing technologies, additive manufacturing (AM) enables the manufacturing of components consisting of highly complex geometries with significant design freedom. In the framework of the Innosuisse project AMminiHyd between industry partner Wandfluh AG and research partners IPPE (FHNW) and inspire AG, an existing conventional hydraulic valve was redesigned for LPBF while considering the current functional and technical requirements. The new design concepts were compared based on CFD simulations, and the chosen concept was then iteratively optimized and finally adapted for manufacturability. The final design was manufactured in stainless steel (1.4404), tested, and compared with the conventionally manufactured valve. This redesign for additive manufacturing leads to substantial improvements, with a reduction in pressure loss of 60% and a weight reduction of 50% compared to the conventionally manufactured design.

Furthermore, the potential for miniaturization was demonstrated by developing and manufacturing a scaled-down version with a channel diameter of 1.5 mm (larger version: 3 mm).

More detailed information can be found in the following article:

Urs Hofmann, Matthias Fankhauser, Simon Willen, Dario Inniger, Christoph Klahn, Kaspar Löffel & Mirko Meboldt (2023) Design of an additively manufactured hydraulic directional spool valve: an industrial case study, Virtual and Physical Prototyping, 18:1, e2129699,

DOI: 10.1080/17452759.2022.2129699

Photo credits: Urs Hofmann (inspire AG)