Precision 3D Scanners by Shining3D

Precision and ease of use combined in powerful scanning solutions, that's what Shining3D's metrology 3D scanners stand for. They are used in applications such as maintenance, reverse engineering or in combination with advanced additive manufacturing techniques.

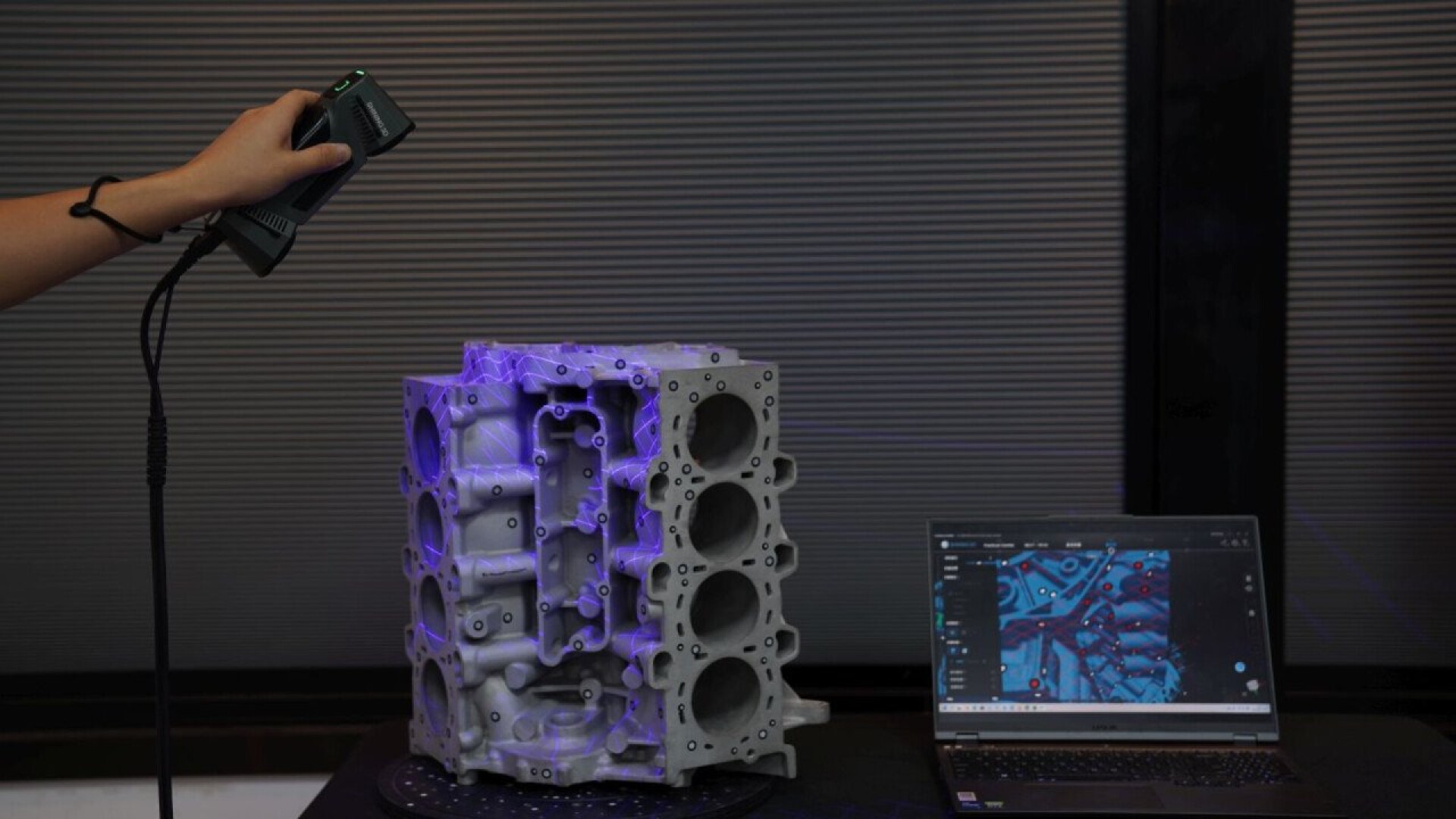

The new Freescan Combo 3D scanner from Shining3D combines two powerful professional scanning technologies in an extremely compact handheld device.

With the help of blue laser lines, even reflective surfaces can be reliably captured. Either 26, 7 or just a single line can be used, depending on whether a lot of surfaces needs to be scanned quickly, an area needs to be captured with high resolution or a hole or similar needs to be scanned as deep as possible.

With structured infrared light, larger areas can be scanned without marking points; in this mode, the scanner orientates itself only by the geometry of an object or a person. By shifting the wavelength into the non-visible range, many sources of interference are eliminated.

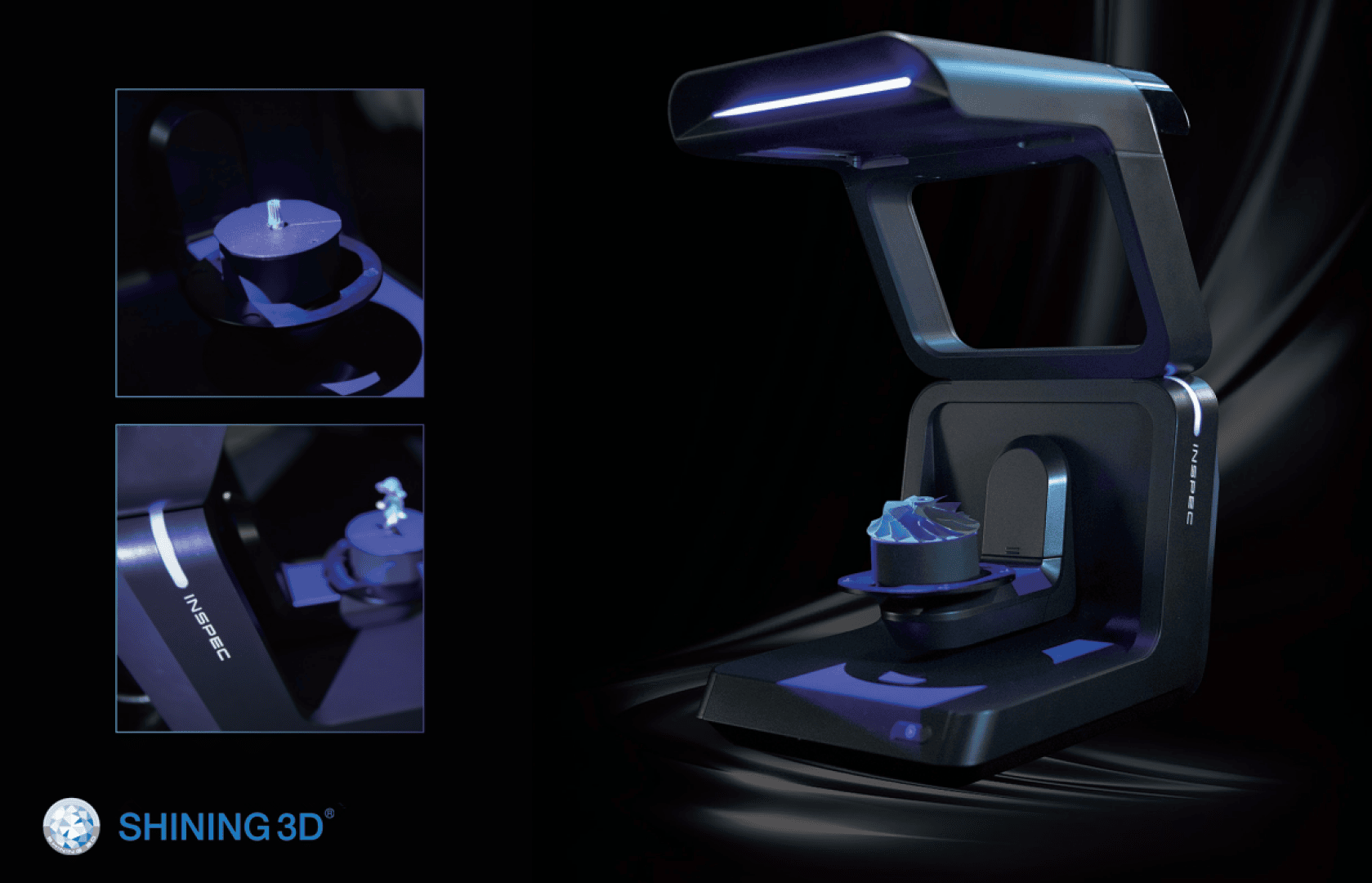

With the stationary Autoscan Inspec 3D scanner, smaller parts can be scanned very quickly and reliably with high precision. With just one turn of the object and a few clicks, a 360° digitization can be achieved - the software merges the individual scans in a few seconds.

The scanner works with structured blue light and does not require any markers on or next to the scanned objects.

Both 3D scanners are used in applications with high accuracy requirements, such as reverse engineering or quality control.