Cool solutions for cutting-edge research

Additively manufactured. Thermally superior.For the Paul Scherrer Institute, Unlimital developed a cooling plate with a flow-optimized geometry – produced using 3D printing. The result: 30% better cooling performance and a new benchmark in detector technology.

Progress Through Research

The Paul Scherrer Institute (PSI) is the largest research center for natural and engineering sciences in Switzerland. At the Center for Photon Science (CPS), an interdisciplinary team develops specialized X-ray detectors for use at synchrotrons and free-electron lasers.

These include systems such as PILATUS, EIGER, GOTTHARD, JUNGFRAU, and MOENCH, which are used at world-renowned facilities like the Swiss Light Source, SwissFEL, and the European XFEL.

These detectors meet the highest standards in resolution, sensitivity, and thermal stability – especially under compact design requirements and the need for precise temperature control.

Additive Cooling Performance for Research Applications

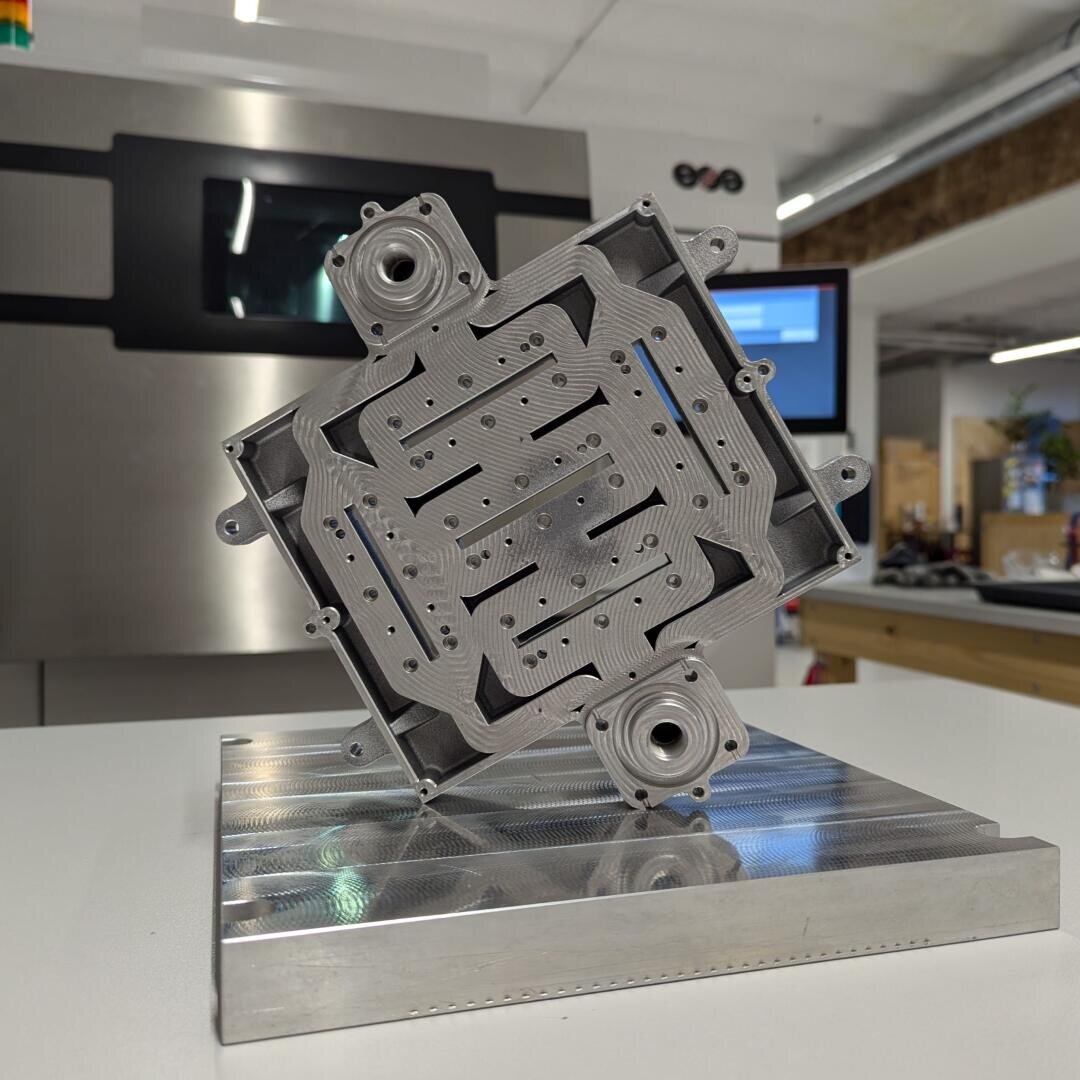

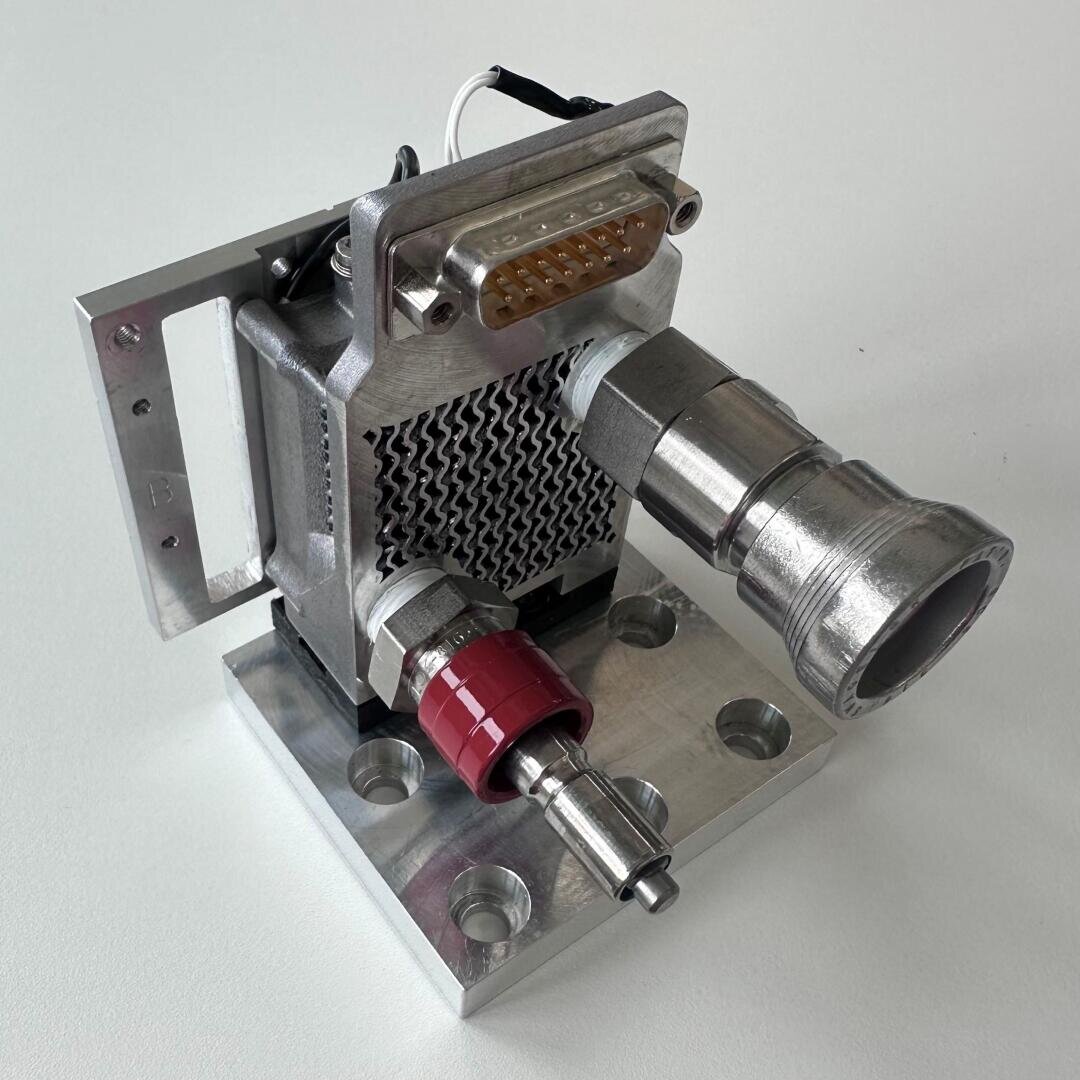

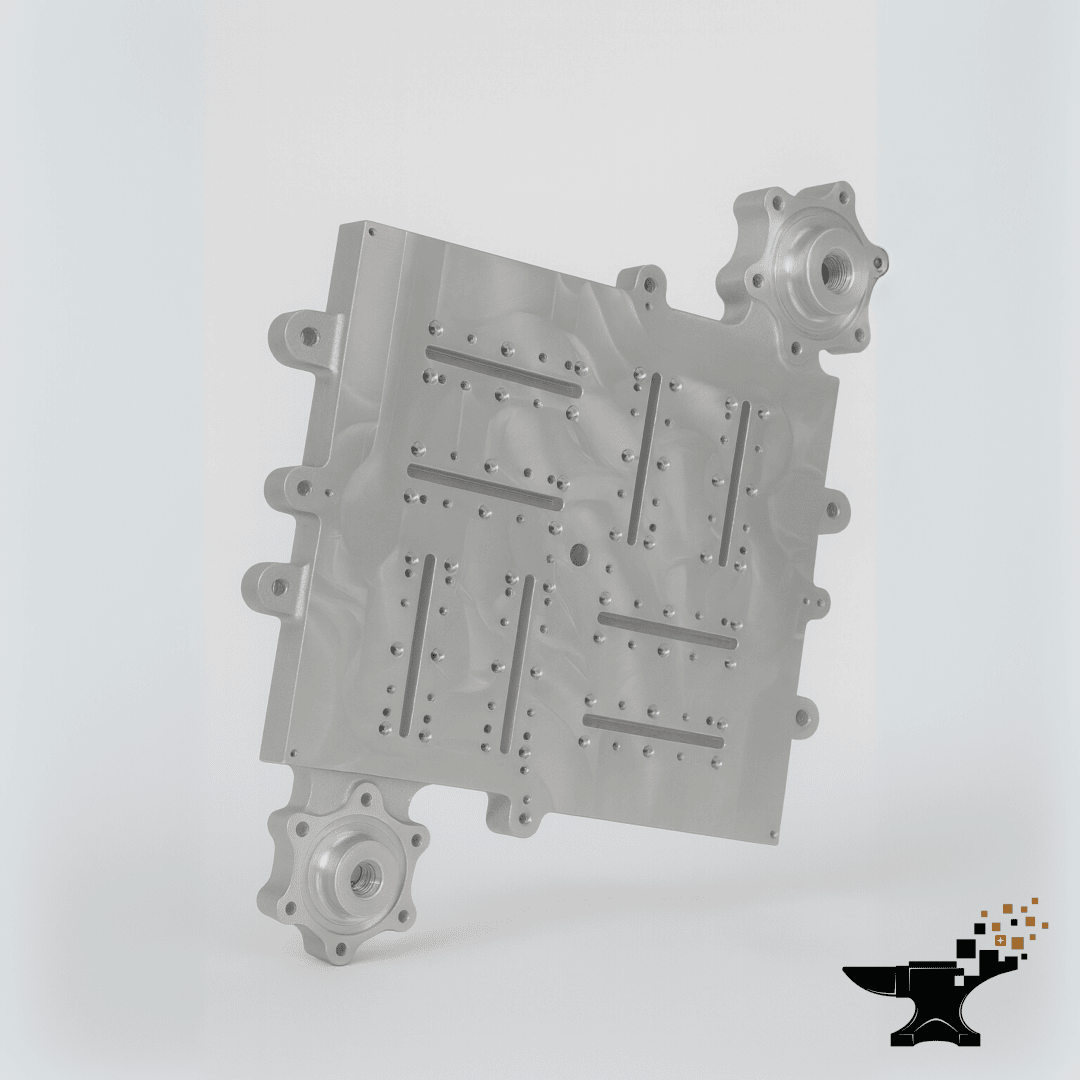

In collaboration with PSI, Unlimital developed a high-performance cooling plate for the EIGER Quad detector module. The goal was to improve heat transfer efficiency, reduce part complexity, and optimally adapt the geometry to the detector.

Thanks to the freedom of additive manufacturing, an internal flow-optimized cooling channel was implemented – a geometry that would not have been feasible with conventional methods like drilling and plugging.

Testing with the new cooling plate demonstrated a temperature reduction of approximately 30 percent compared to the previous design. This result represents a clear improvement in thermal performance.

Even more promising is the fact that the insights gained from the EIGER Quad project are already being applied to further projects at PSI. This makes the collaboration an important contribution to the ongoing development of next-generation cooling systems in cutting-edge research.

Feedback from PSI

“Additive manufacturing gives us new design freedom in the development of cooling solutions, especially for complex geometries. With the new cooling plate, we were able to specifically influence the thermal behavior and improve overall system stability.”

“Working with Unlimital has been highly professional and pleasant. We particularly appreciate the close collaboration, fast response times, and technical expertise. Compared to previous partners abroad, the short distances are a major advantage.”

— Shqipe Hasanaj, Mechanical Engineer, PSI

3D-Printed Solutions for Real-World Challenges

This project shows how additive manufacturing can advance scientific research in measurable ways. Optimized cooling structures, short development cycles, and close cooperation lead to solutions that are both precise and scalable.

The insights gained have already been applied to other cooling systems, further enhancing the performance of our components.

Planning a Project With Advanced Cooling Requirements?

We’re here to support you – from the initial idea to the finished component. Get in touch with us if you're looking for a reliable solution for your thermal challenges