Print & Place

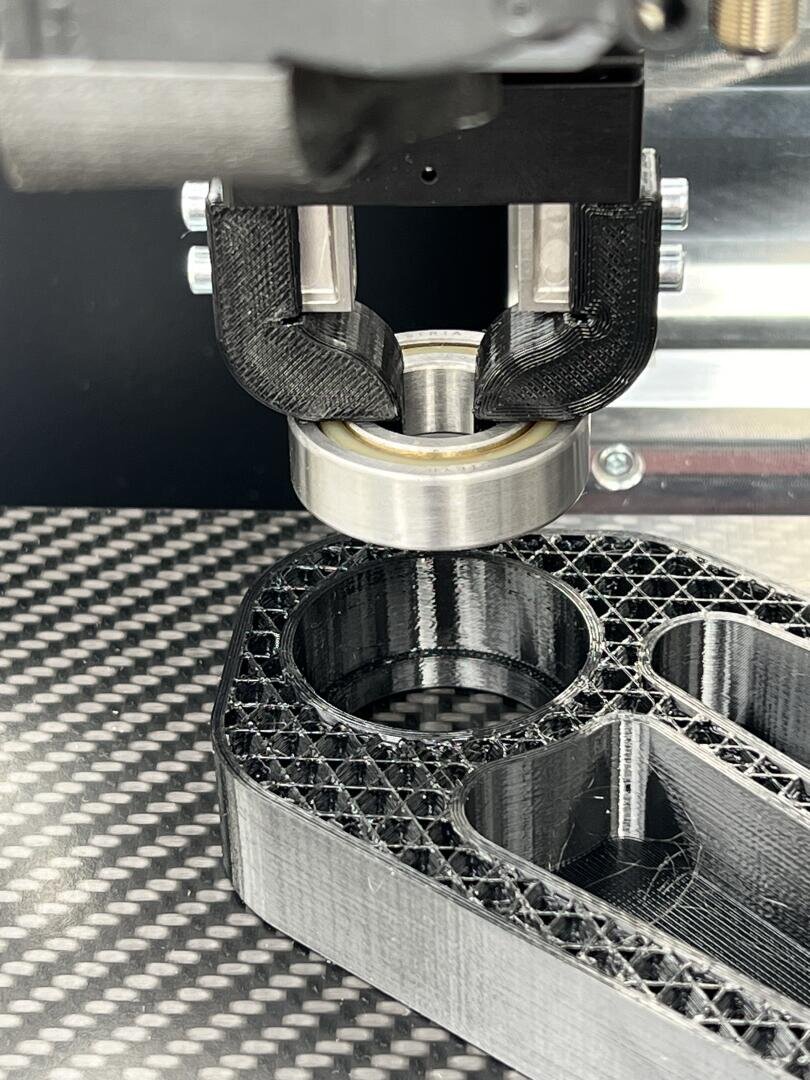

“Print & Place”, a new feature of APS's W2.0 flagship 3D printers, components and molded parts can be integrated directly into the printed component in one single printing process.

“Using our now established and widely used continuous fiber printing technology, with ‘Print & Place’ we can integrate machine components, standard parts, etc. directly into the printed component ,” explains Bernd Lechner, senior technician at APS. Component diversity, individual manufacturing steps and associated machine downtime are reduced to a minimum with this insertion technology. Different manufacturing techniques are combined. Automatic feeders, including separation or tray feeders directly on the printing plate, enable closed manufacturing within our 3D printing system. “With a complete enclosure, we automatically integrate RFID tags, for example, directly into the printed component on the printing plate without the need for manual loading and unloading. This significantly reduces production time, increases quality, and reduces production costs,” Lechner continues.

“Print & Place” can be retrofitted to new printers in the W2.0 series as well as upgraded to existing APS 3D printers. APS's interdisciplinary expertise is evident here: with over 40 years of company history, APS is not only a 3D printer developer and manufacturer, but also an experienced developer and manufacturer of industrial robotics and production systems.