Additive Manufacturing in Series Production

Additive manufacturing is evolving from prototyping to series production. This article explores where the technology stands today – and the opportunities and challenges in industrial applications.

Additive Manufacturing in Series Production

Ready for Series Production – Under the Right Conditions

In certain industries such as medical technology, aerospace, or motorsport, additive series production is already a reality. The key factor is not necessarily the volume, but the combination of design freedom, customization, and short delivery times.

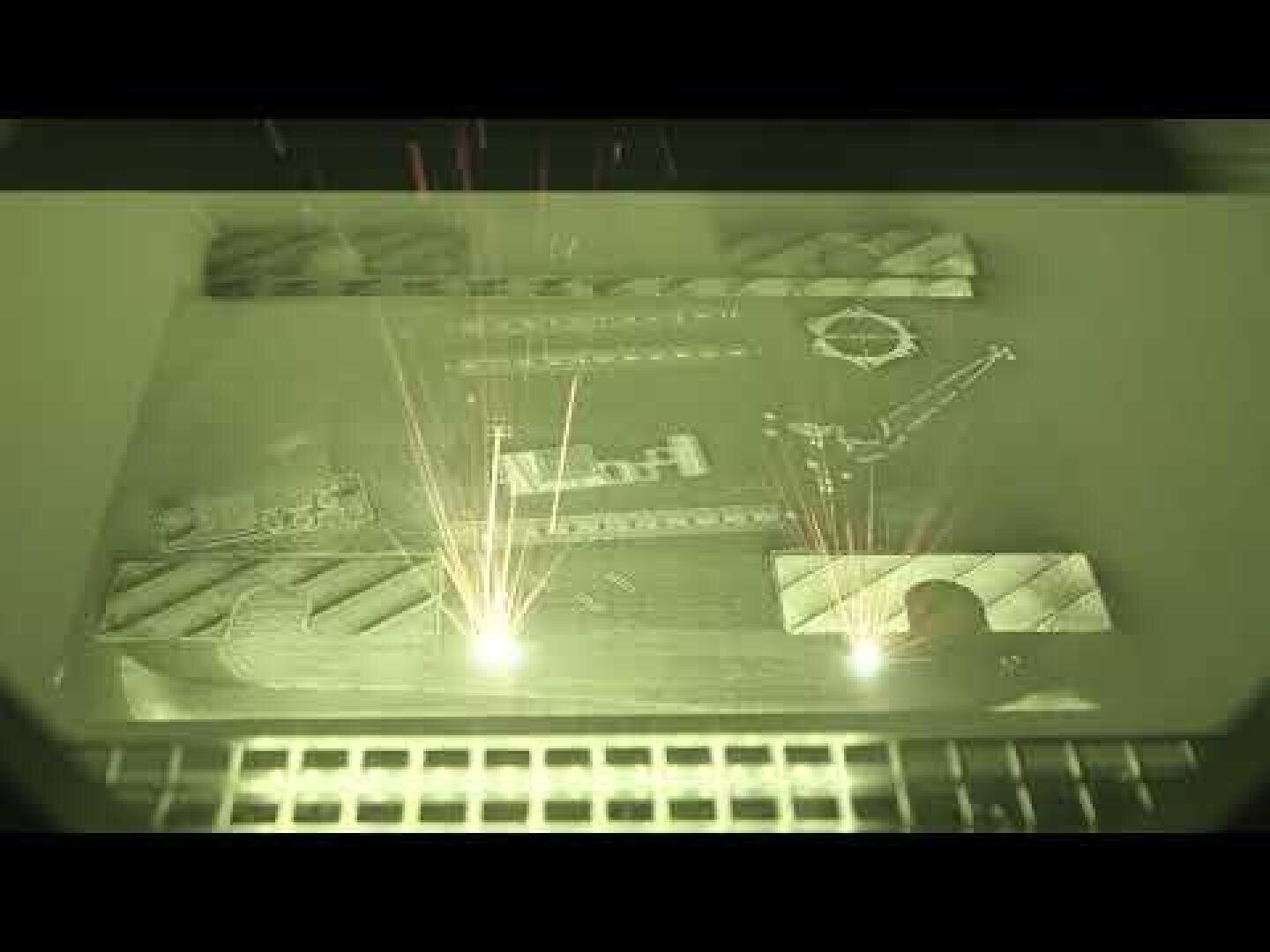

An example of an industrial solution is the DMP Flex 350 Dual system from 3D Systems. This metal 3D printer operates with two lasers, significantly increasing build speeds while maintaining high part quality. Its potential is particularly evident in small series production of complex metal components.

According to the manufacturer, the DMP Flex 350 Dual is ideally suited for producing parts made of titanium, Inconel, or stainless steel – for example, aerospace components or medical implants. Its closed powder management system also ensures a safe and stable production process.

🔗 Source: 3D Systems – DMP Flex 350 Dual

Cost-Effective from a Single Unit

Thanks to intelligent process control, automated powder handling, and minimal setup effort, additive manufacturing now offers economic advantages in series production – especially for complex or highly customized parts. The quantity becomes a secondary factor: individualized series starting from a single unit are feasible – fast, reliable, and repeatable. With systems like the DMP Flex 350 Dual, components can not only be designed but specifically optimized for 3D printing – a true competitive advantage in modern manufacturing.

Conclusion:

Additive manufacturing has arrived in series production. Machines like the DMP Flex 350 Dual make it possible to produce high-quality metal parts economically and flexibly – from single pieces to small industrial series. Those who invest today are laying the foundation for future-proof production processes.