Expansion in quality assurance: precise results thanks to laser scanner

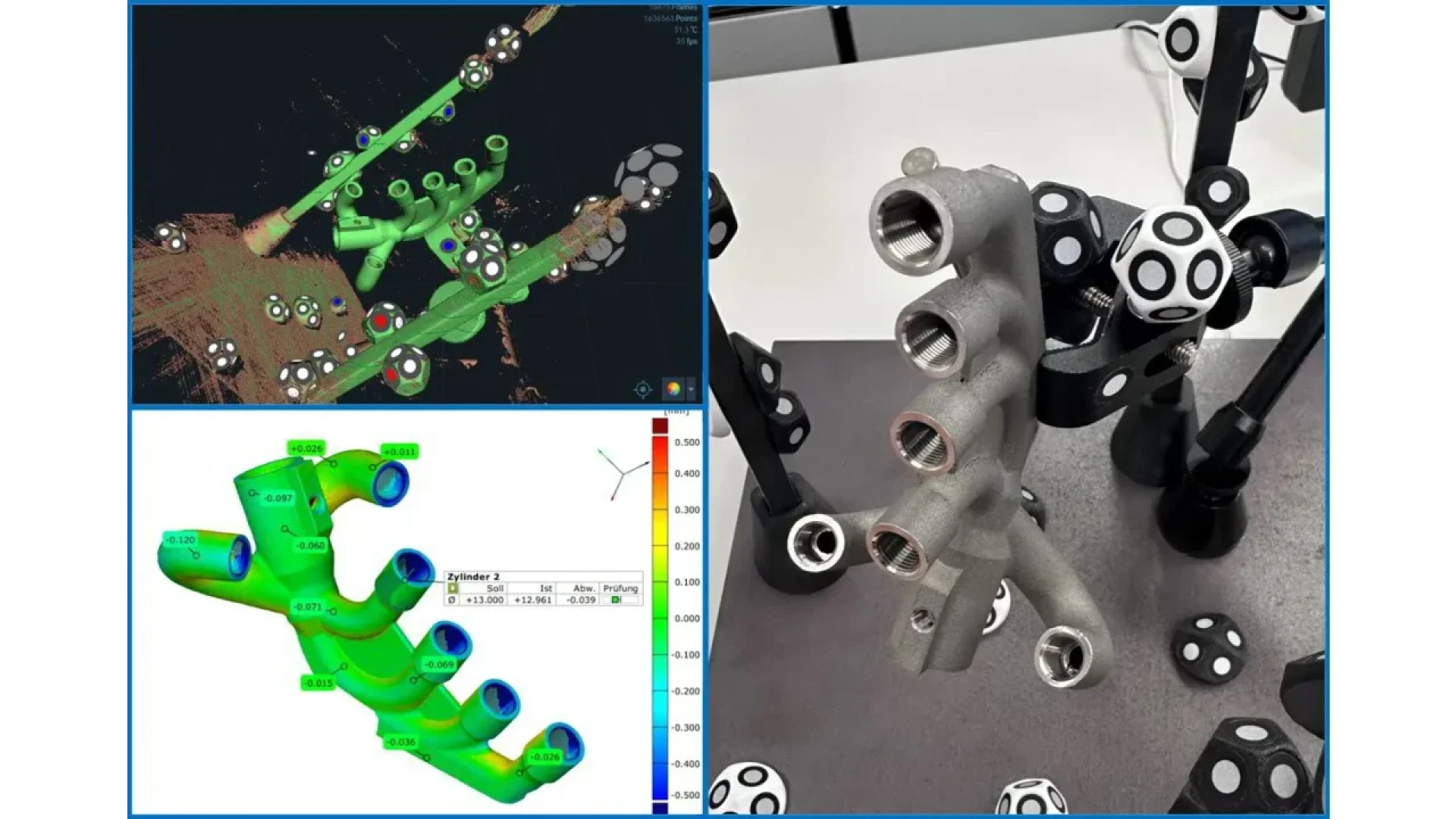

Feramic AG is driving additive metal manufacturing forward with the highest precision. For quality assurance, we use state-of-the-art laser scanning technology that digitizes, measures and analyses components with an accuracy of up to 0.02 mm.

Your advantages at a glance:

- Precise quality control: Our new laser scanner makes even the smallest deviations visible. A direct comparison with the 3D model ensures the precision of your components.

- Comprehensive documentation: We offer detailed inspection reports and measurement logs for seamless quality assurance.

- Process optimization: The scan data flows directly into our production software, optimizing future production processes. This allows us to manufacture your components perfectly right from the start.

More than just inspection: reverse engineering

In addition to quality control, our laser scanner opens up exciting possibilities in the field of reverse engineering. Defective or rare components - such as spare parts for classic cars - can be digitally reconstructed and reproduced with precision. This enables fast, reliable and exact reproduction.

Would you like to find out more about our quality assurance?

Contact us today and discover how we can take your products to the next level with state-of-the-art technology.