Advancing High-Precision Additive Manufacturing: From LPBF to Lithography-Based Processes

Discover how high-precision LPBF and innovative lithography-based processes with enhanced resolution and superior surface quality drive the development of novel products.

Additive manufacturing (AM) has revolutionized the fabrication of industrial components by overcoming the limitations of conventional manufacturing, particularly in terms of shape complexity. This advancement enables the creation of more integrated and lightweight solutions. Despite its significant advantages in design complexity, AM still has room for improvements in precision and surface finish. As the technology matures, the focus is shifting towards exploring the potential of AM in high-precision manufacturing with productivity enabling industrialization.

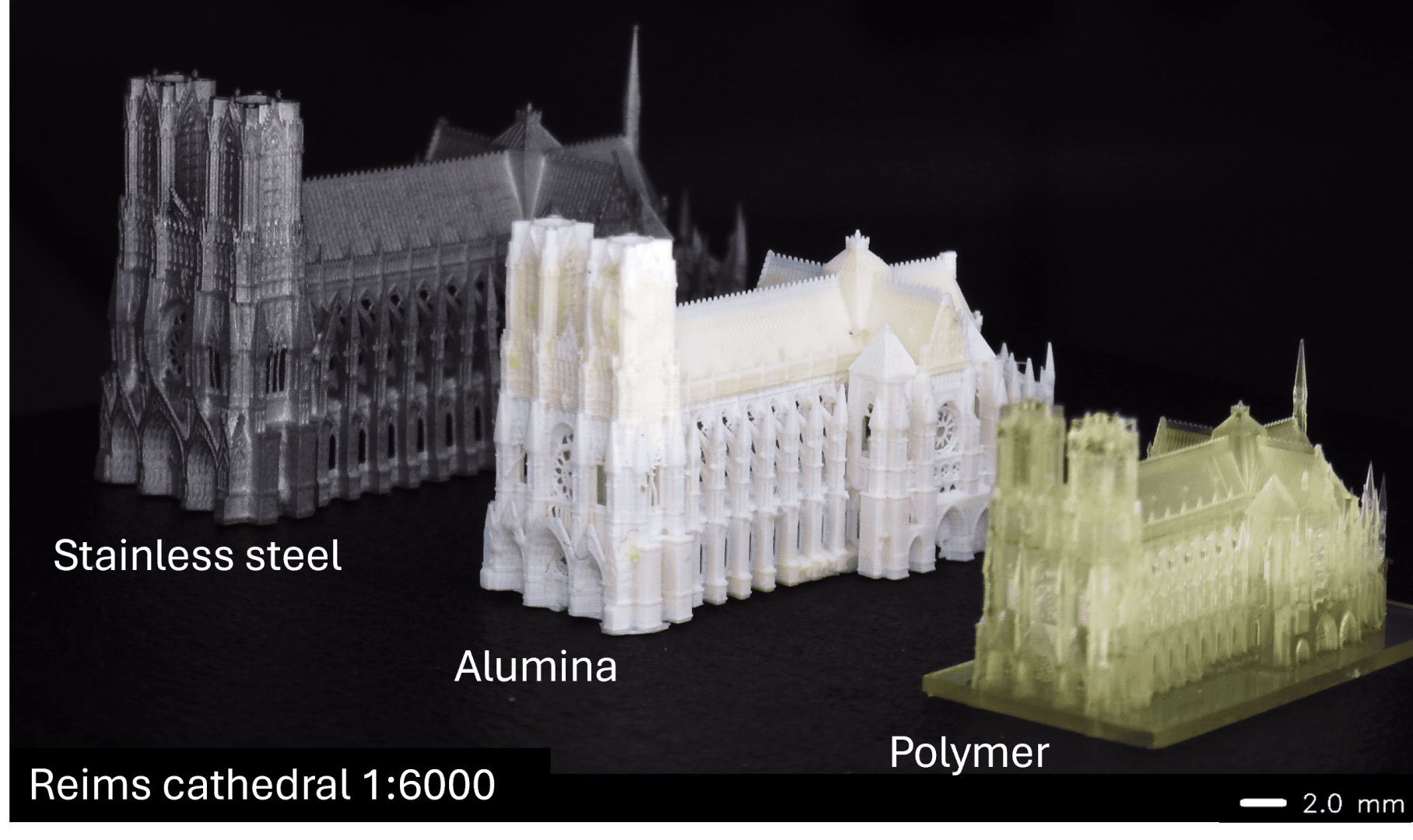

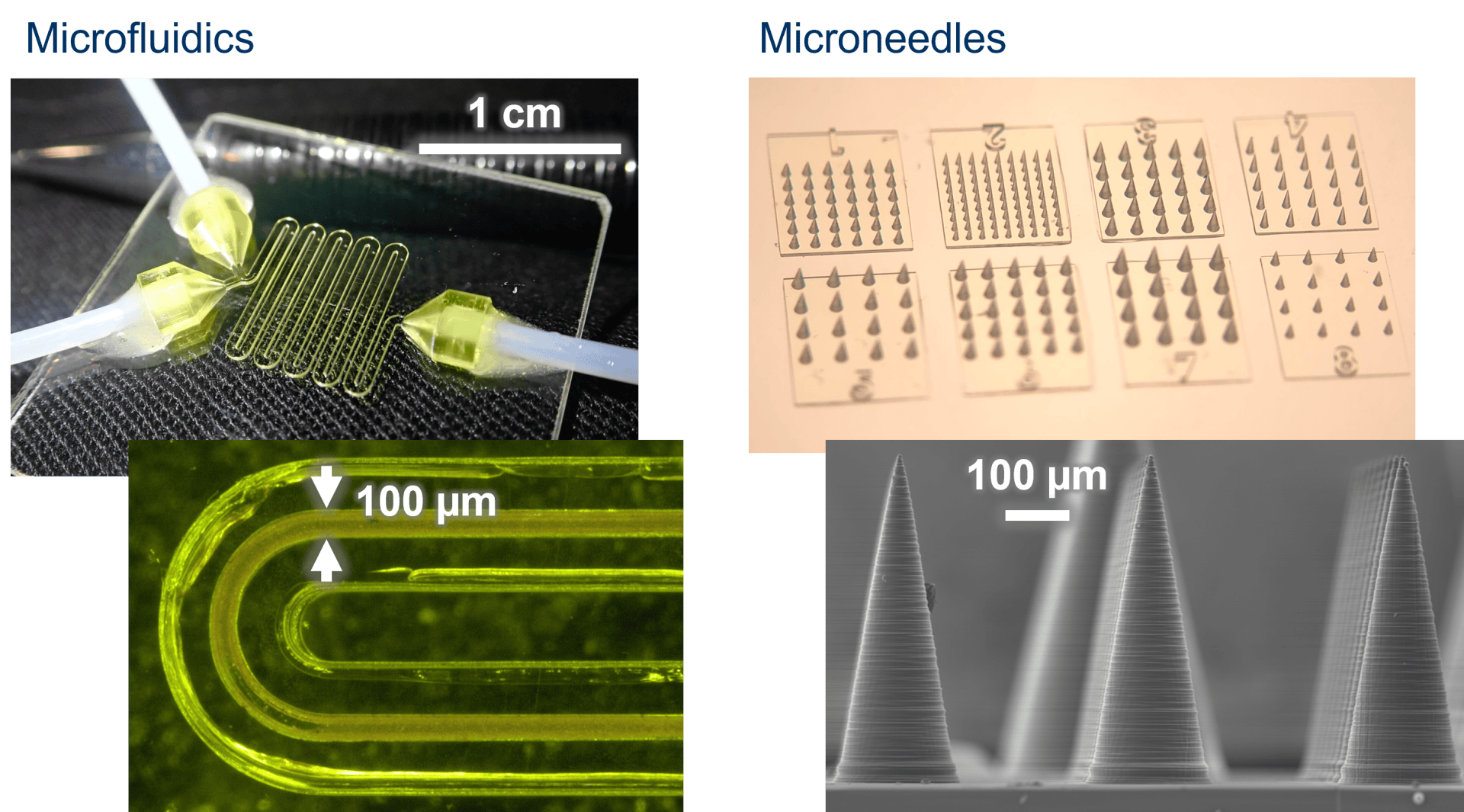

In the realm of high-precision AM, CSEM is invested in process optimization with new-generation LPBF hardware, coupled with advanced laser exposure strategies. We are also developing two lithography-based approaches: one sinter-based and the other electrodeposition-based. Our sinter-based process allows for production comparable to metal injection molding, but without the need for molds. Meanwhile, our electrodeposition-based process offers even higher resolution and superior surface quality, opening new possibilities for micro-component fabrication.